No Products in the Cart

Infrared Scanning can prevent electrical fires. More specifically, it's essential to involve the use of predictive maintenance by involving infrared thermographic scanning, known commonly as "IR scanning." We'll explore how this powerful tool helps identify electrical failures before they result in potentially devastating fires. Whether in industrial plants, commercial buildings, or high-rise structures, electrical faults and failures often lead to fires. Additionally, IR scanning can help identify energy inefficiencies and roof leaks. The good news is that many electrical fires can be prevented through use of infrared thermography.

Throughout my career in industry, one thing has remained clear: electrical equipment failures are often the root cause of catastrophic fires. This isn’t just a theoretical risk—these fires happen regularly, and many of them could have been prevented with the right precautions. Electrical systems, whether in homes, warehouses, or factories, are constantly under stress, and when things go wrong, they can go very wrong.

Take, for example, a simple story. A friend was dealing with frequent circuit breaker tripping. When the electrician came to check it out, they discovered that the circuit panel was packed with tandem half-size “slimline” breakers to add more circuits. Unfortunately, this setup wasn’t compliant with regulations, and two of the breakers had overheated to the point of melting, creating a severe fire hazard. This scenario serves as a clear reminder that electrical safety is to be taken very seriously, as it’s easy to overlook small but crucial details that could prevent disasters.

The key takeaway here is that many electrical systems are designed with safety features in mind, but only when properly maintained and installed. Overloading circuits, using non-compliant parts, or failing to replace outdated equipment increases the chances of failure—potentially increasing the risk of fire. This is where preventive maintenance becomes critical.

The Role of Infrared Scanning in Predictive Maintenance

Now let’s look at the broader industrial world, where the risks are even greater. In places like warehouses, factories, and commercial buildings, massive electrical loads are common. And the more power we use, the more the system is susceptible to failure. Overloaded breakers, loose connections, worn-out motors, and even animal nests inside distribution equipment all pose significant fire risks.

Here’s the thing: many industrial facilities haven’t updated their electrical systems in years—or worse, they’ve never been properly inspected at all. This lack of maintenance can lead to unexpected electrical failures and fires, which could have been avoided with proactive measures. One of the most effective preventive tools available today is infrared scanning using infrared thermography.

How Infrared Thermography Works

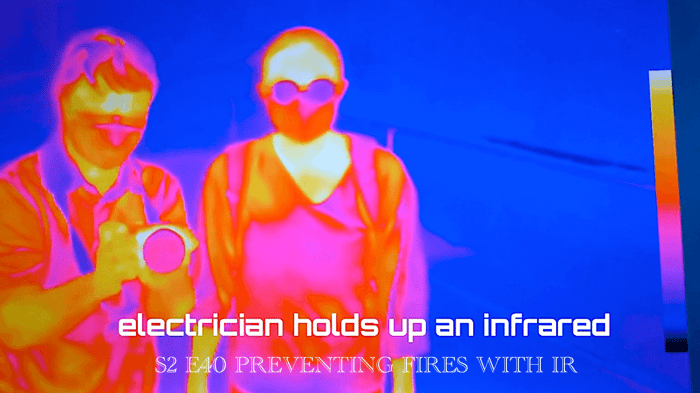

So, how does infrared thermography, or infrared scanning, help? Imagine an electrician holding an infrared camera up to a live electrical panel. The camera’s screen would light up, displaying heat signatures and clearly indicating areas of concern. Whether it’s a loose connection, an overloaded circuit, a failing motor, or damaged insulation, the camera reveals exactly where the problem lies—long before it becomes a fire hazard.

Infrared scanning is a non-contact, non-destructive method for detecting potential electrical and mechanical issues. Unlike traditional inspection methods, IR scanning doesn’t require taking equipment offline or causing any disruption to operations. That’s one of the reasons it’s such a valuable tool in predictive maintenance. Instead of waiting for a system to fail catastrophically, you can spot early warning signs and take corrective action before things go wrong.

The Benefits of Infrared Scanning in Preventive Maintenance

The advantages of infrared thermography are numerous. By using infrared cameras with qualified thermographers, you can spot issues early on. For example:

Infrared scanning is a game-changer because it offers instantaneous results. When the thermographer points the camera at a piece of equipment, they immediately get feedback on the temperature distribution, which they can then use to determine the health of the system. This proactive approach to maintenance allows you to address problems before they lead to a breakdown, a safety incident, or worse—an electrical fire.

How IR Scanning Helps Prevent Electrical Fires

The real value of infrared thermography in preventing fires lies in its ability to identify heat anomalies. Electrical systems often begin to overheat before failure occurs, and this heat buildup can be easily spotted with an infrared camera. If a connection is loose or a motor is wearing out, the area will show up as hotter than its surroundings. Over time, these temperature differences can cause components to degrade, leading to catastrophic failures and fires.

Let’s break this down:

The Bottom Line: Infrared Scanning Saves Lives and Money

Incorporating infrared thermographic scanning into your preventive maintenance program is more than just a good idea—it’s a necessity for any operation that uses electrical systems. Whether it’s a manufacturing plant, a distribution center, or even a commercial building, the importance of regular IR inspections cannot be overstated.

By catching potential issues before they lead to fires or system failures, infrared thermography helps to ensure the safety of your workers, protect valuable assets, and keep operations running smoothly. The benefits are clear: less downtime, reduced costs, and a safer, more efficient operation.

If your organization hasn’t yet implemented infrared thermography as part of its predictive maintenance strategy, now is the time to start. Consider running pilot inspections at a few facilities and see the difference it can make. The insights you gain could be invaluable and help prevent costly—and potentially devastating—incidents down the line.

In addition to protecting your facility, don't forget to check out MightyLineTape.com for durable floor striping and floor signage solutions that can improve safety in your warehouse or manufacturing environment. Also be sure to check out their “shapes and symbols,” clear "windows" (label protectors) for scan codes, and ANSI/ISO safety color and symbol guides.

Thanks for joining us on our Mighty Line Blog today! Stay safe and remember: knowledge and prevention are the best defenses against electrical hazards and fires.