No Products in the Cart

Upgrading Warehouse Technology: Optimize Business Success

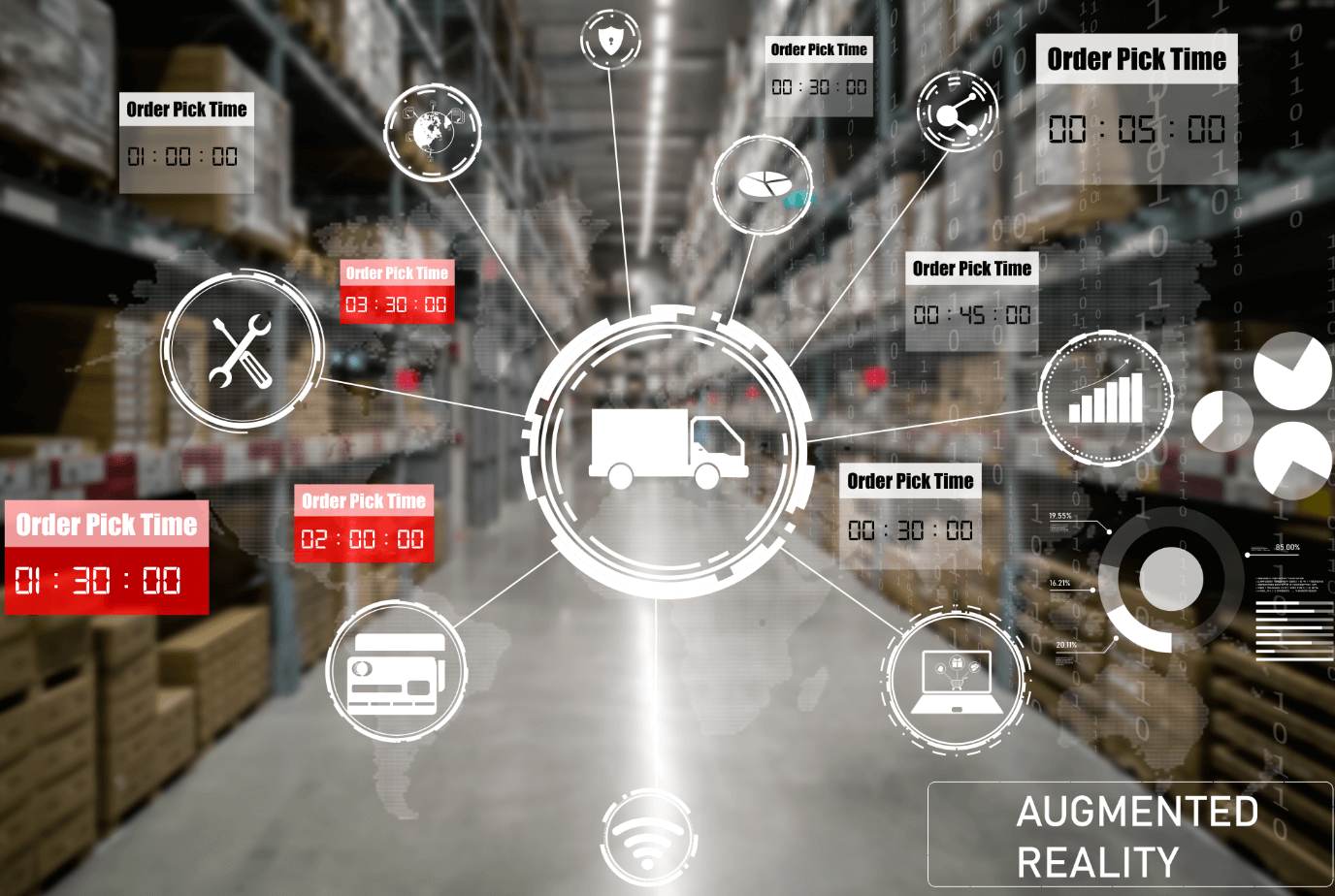

In today's rapidly evolving business landscape, staying ahead of the competition requires continuous adaptation and innovation. One area where businesses can significantly improve their efficiency and productivity is by upgrading the technology in their warehouses. Embracing the latest advancements can enhance inventory management, streamline operations, and optimize the overall supply chain. In this article, we will explore the key considerations businesses should keep in mind when upgrading their warehouse technology, ensuring a successful transition towards a more modern and efficient operation.

Assess Your Current Infrastructure

Before diving into any upgrades, it's crucial to assess your current warehouse infrastructure. Conduct a thorough evaluation of your existing technology, processes, and systems. Identify pain points, bottlenecks, and areas that could benefit from improvement. This assessment will provide valuable insights into the specific technologies and solutions that can address your unique business needs.

Embrace Automation and Robotics

In the age of automation, integrating robotics into your warehouse operations can revolutionize productivity. Automated guided vehicles (AGVs) and robotic picking systems can handle repetitive tasks, allowing your staff to focus on more value-added activities. Additionally, warehouse management systems (WMS) can automate inventory tracking, optimize storage space, and facilitate real-time order processing. By embracing automation, you can minimize human errors, improve accuracy, and increase throughput.

Utilize Data Analytics

Unlocking the power of data analytics is vital for optimizing warehouse performance. Implementing a robust data analytics platform enables you to gain actionable insights into inventory levels, demand patterns, and operational efficiencies. Leveraging data, you can make informed decisions regarding stock replenishment, demand forecasting, and resource allocation. By utilizing the advantage of analytics, you can optimize your supply chain, cut costs, and boost customer satisfaction.

Implement IoT and RFID Technology

The Internet of Things (IoT) and Radio Frequency Identification (RFID) technology have transformed the way warehouses operate. IoT devices, such as sensors and connected devices, can provide real-time data on inventory levels, equipment status, and environmental conditions. RFID technology enables automated tracking and tracing of goods, reducing manual labor and minimizing errors. By implementing IoT and RFID, you can enhance inventory accuracy, improve order fulfillment, and streamline the overall supply chain.

Enhance Warehouse Connectivity

Having a connected warehouse is essential for seamless operations. Invest in a robust wireless network infrastructure to ensure reliable connectivity throughout the facility. This connectivity enables real-time communication between warehouse staff, automated systems, and management. With enhanced connectivity, you can track inventory in real-time, optimize pick routes, and improve overall operational efficiency.

Consider Warehouse Robotics

Incorporating warehouse robotics can significantly boost productivity and accuracy. Consider implementing autonomous mobile robots (AMRs) for tasks like picking, sorting, and material handling. These robots can navigate the warehouse autonomously, working alongside human workers to optimize operations. By introducing robotics, you can reduce labor costs, improve picking accuracy, and accelerate order fulfillment.

Invest in Cloud-Based Systems

Traditional, on-premises software systems are becoming obsolete in the face of cloud-based solutions. Cloud-based warehouse management systems offer scalability, flexibility, and accessibility from anywhere, at any time. They eliminate the need for costly infrastructure investments, providing seamless updates and integration with other business systems. Cloud-based systems also offer enhanced data security, automatic backups, and disaster recovery options.

Prioritize Cybersecurity

As technology advances, the risk of cyber threats also increases. Upgrading your warehouse technology necessitates a strong focus on cybersecurity. Implement robust security measures to protect sensitive data, both on-premises and in the cloud. This includes firewalls, encryption, multi-factor authentication, and regular security audits. By prioritizing cybersecurity, you can safeguard your business and customer information, maintain operational continuity, and prevent costly data breaches or disruptions.

Ensure Scalability and Future-Proofing

When upgrading warehouse technology, it's important to consider scalability and future-proofing. Choose solutions that can accommodate your business's growth and evolving needs. Look for flexible systems that can be easily upgraded or integrated with new technologies in the future. This approach ensures that your warehouse remains adaptable and capable of supporting your business's long-term goals.

Train and Engage Your Workforce

Introducing new technologies requires a workforce that is trained and prepared for the changes. Provide comprehensive training programs to educate your employees on the upgraded technologies and systems. Foster a culture of continuous learning and encourage employee engagement in the adoption process. By involving your workforce and addressing their concerns, you can minimize resistance, maximize productivity, and create a smoother transition to the upgraded warehouse technology.

Consider Return on Investment (ROI)

Upgrading warehouse technology involves a significant investment. Before making any decisions, conduct a thorough cost-benefit analysis to evaluate the potential return on investment. Consider factors such as increased productivity, reduced labor costs, improved accuracy, and enhanced customer satisfaction. Calculate the payback period and assess the long-term benefits of the technology upgrades. This analysis will help you make informed decisions and prioritize the most valuable investments for your business.

In today's competitive business landscape, upgrading warehouse technology is crucial for staying ahead of the curve. By embracing automation, data analytics, IoT, robotics, and cloud-based systems, businesses can optimize their operations, increase productivity, and improve customer satisfaction. However, successful implementation requires careful consideration of the current infrastructure, scalability, cybersecurity, ROI, and effective employee engagement. By incorporating these key considerations into your warehouse technology upgrade strategy, you can pave the way for a more efficient, streamlined, and future-ready supply chain, positioning your business for sustained growth and success in the dynamic market.

Go to MightyLineTape.com/SafetyTips to request a Sample Pack of their incredible Safety Signs and Floor Markings.