No Products in the Cart

Warehouse safety topics remain a critical concern as workplace accidents continue to affect thousands of workers annually, with over 5,000 serious injuries reported in warehouses last year alone. However, preventing these accidents doesn't always require complex solutions or expensive equipment upgrades. Simple changes in layout, equipment maintenance, and safety protocols can significantly reduce workplace hazards. Specifically, implementing basic warehouse safety tips and adhering to OSHA regulations can create a safer environment for everyone.

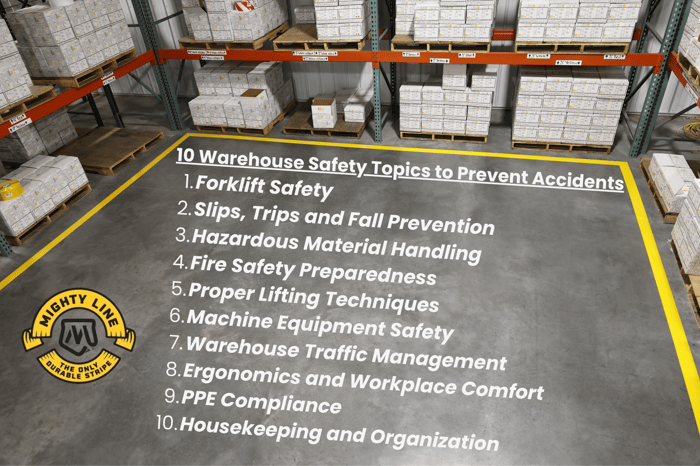

This guide explores practical solutions to common warehouse safety challenges. From improving layout design to establishing clear safety zones and conducting regular safety inspections, we'll cover the top 10 warehouse safety tips that can help prevent major accidents and protect your workforce.

The transportation and warehousing industry faces serious safety challenges, ranking second only to emergency services in workplace accident rates. According to recent data, warehouse workers experience injury rates more than double the national average, with 5.5 incidents per 100 workers compared to 2.7 across all industries [1].

Forklift accidents stand as one of the most devastating causes of warehouse injuries. Although these incidents make up only 1% of warehouse accidents, they result in approximately 20,000 serious injuries and 100 deaths annually [2]. Furthermore, forklift impacts cause 90% of pallet rack failures [3], creating additional hazards from falling materials and structural damage.

The loading dock area presents particularly high risks, with 25% of all industrial accidents occurring in this location [4]. Most notably, workers face crushing injuries between forklifts and trailers during loading and unloading operations. Additionally, struck-by injuries account for 16% of warehouse fatalities [4]. Proper training on powered industrial trucks and implementing safety measures for conveyor systems can help mitigate these risks.

However, when serious accidents and injuries do occur due to negligence, consulting with a skilled personal injury lawyer can be a crucial step for affected workers and their families to understand their rights and seek compensation.

Falls remain among the most frequent causes of serious work-related injuries, with 8% of warehouse injuries resulting from falls to lower levels [2]. OSHA mandates fall protection for any working surface above four feet in general industry workplaces [5]. Nevertheless, statistics show that over 40% of fatal falls occur from heights lower than 15 feet [6].

To prevent these incidents, employers must:

Install guardrails and toe-boards around elevated platforms

Provide safety harnesses and lines where necessary

Ensure proper maintenance of ladders and elevated work surfaces

Guard floor holes that workers might accidentally walk into

Additionally, addressing slips, trips, and falls at ground level is crucial for overall warehouse safety.

Musculoskeletal disorders affect numerous warehouse workers, primarily due to repetitive motions and improper lifting techniques. Overexertion leads the list of injury causes, accounting for nearly 30% of all transportation and warehousing injuries [2]. These injuries typically manifest as sprains or strains to the back and shoulders.

Several factors contribute to manual handling injuries:

Repeated forceful motions while moving boxes

Uncomfortable work positions requiring twisting and reaching

Extended periods without adequate rest breaks

Cold storage conditions affecting blood circulation

High-stress environments with unrealistic production standards [7]

The severity of these injuries becomes apparent when examining recovery times. Data shows that 39% of warehouse injuries result in workers being away from work for 31 days or more per incident, compared to 23% across all industries [1]. Moreover, the warehousing DART rate (Days Away, Restricted, or Transferred) stands at 4.6, more than double the 1.7 rate of private industry workers [1].

Notably, awkward postures contribute to 11.3% of injuries [2], while inadequate training and poor communication often compound these risks. Workers frequently develop symptoms gradually, initially trying to ignore pain, tingling, or numbness in their back, neck, shoulders, arms, wrists, and hands [7]. Consequently, these conditions often worsen and become harder to treat when left unaddressed.

Implementing proper ergonomics practices and providing regular training on safe lifting techniques can significantly reduce these injuries.

Basic layout modifications can dramatically reduce workplace accidents in warehouses. Two fundamental changes - proper floor marking tape like Mighty Line floor tape and Floor signs and strategic lighting placement - create safer working conditions without major infrastructure investments.

Floor marking tape serve as vital visual guides that separate spaces and direct traffic flow safely throughout the warehouse. A well-organized marking system helps prevent collisions between pedestrians and machinery by creating designated paths for each [8].

Floor striping using industrial-grade materials offers multiple safety benefits:

Separates motorized traffic from foot traffic to minimize accident risks

Defines specific workstations and storage zones

Marks areas requiring personal protective equipment

Highlights potential hazards and restricted zones [9]

For maximum effectiveness, Mighty Line warehouse floor markings typically use color-coding to indicate different zones and hazard levels. Red and yellow markings denote hazardous areas, often using alternating patterns for enhanced visibility [10]. These markings must remain clearly visible at all times - regular maintenance ensures they continue providing clear visual guidance for safe navigation [11].

Strategic lighting placement stands as another crucial yet straightforward safety improvement. Poor lighting contributes directly to accidents, especially in areas with moving machinery or high-stack storage zones [12].

Proper warehouse lighting requires careful consideration of several key factors:

First, light fixtures need strategic positioning to eliminate shadows and ensure uniform illumination. As a standard practice, lights are mounted on the ceiling and centered over aisles to prevent rack structures from creating dark spots [13]. This arrangement helps operators maintain visual clarity while performing their tasks.

Second, different areas require varying light intensities based on specific activities. Loading docks demand particularly bright illumination because of frequent forklift movements and product handling [13]. Similarly, order picking zones need enhanced lighting for accurate product identification and proper handling [14].

LED lighting systems offer significant advantages for warehouse applications:

Provide consistent, bright illumination

Reduce energy consumption by up to 30%

Feature longer operational life

Include motion sensor capabilities for automated control [14]

Installing anti-glare LED fixtures with frosted lenses or reflectors helps eliminate visual discomfort that could lead to accidents [14]. Additionally, incorporating smart controls allows for automatic adjustment based on occupancy, further enhancing both safety and energy efficiency.

The combination of proper lighting and clear floor markings creates a safer warehouse environment where workers can:

Navigate confidently through designated paths

Identify potential hazards quickly

Perform tasks with greater precision

Maintain better concentration levels throughout their shifts [14]

These straightforward layout modifications prove that effective safety improvements don't always require complex solutions. By implementing clear walkway markings and optimizing lighting placement, warehouse operators can significantly reduce accident risks while improving operational efficiency.

Proper equipment maintenance and safety measures form the backbone of warehouse accident prevention. A well-maintained warehouse with appropriate safety installations can cut down operational risks substantially.

Implementing systematic equipment inspections prevents malfunctions that could lead to accidents. Data shows that poorly maintained equipment stands as a significant hazard in modern warehouses that use forklifts, conveyor belts, and pick-to-light technologies [15].

A comprehensive maintenance program includes:

Daily pre-start equipment inspections to identify damage

Scheduled preventive maintenance during off-peak hours

Documentation of all maintenance activities and repairs

Regular weight capacity verification for storage systems

Scheduling maintenance when the warehouse isn't operating helps avoid disrupting regular operations. Still, maintenance shouldn't be postponed even if optimal timing isn't possible, since emergency repairs often require longer downtimes [16].

It's crucial to implement lockout/tagout procedures during maintenance to prevent accidental equipment startup and protect workers from electrical hazards.

Physical barriers play a vital role in protecting both workers and equipment. Machine guards create secure zones around automated systems, effectively separating personnel from dangerous machinery [17].

Essential safety guard components include:

Robot Cell Enclosures: These interlocked barriers establish secure perimeters around automated robotic systems, preventing unauthorized access [17].

Conveyor Guards: Access-controlled protective gates shield workers from moving conveyor components, reducing the risk of entanglement accidents [17].

End-of-Aisle Protectors: These safeguard the bottom of rack uprights where 90% of forklift impacts occur [1]. The wrap-around design protects the entire depth of the frame, offering maximum protection at intersecting aisles where forklift traffic is heaviest.

Column Protectors: Impact-absorbing protectors surround facility columns, minimizing structural damage from vehicle collisions [4].

Proper storage of equipment reduces accidents and extends machinery lifespan. Charging stations, undoubtedly, require particular attention since they present unique safety challenges [3].

Key considerations for equipment storage include:

Charging Station Safety: These areas must feature:

Proper positioning of forklifts with applied brakes

Fully charged fire extinguishers readily available

Required personal protective equipment

Overhead hoists for battery servicing [3]

Equipment Placement: Strategic positioning of machinery helps maintain clear pathways and reduces collision risks. Storage zones should have:

Clear weight capacity labels on shelves

Safe access means for storing and removing items [15]

Designated areas for different equipment types

Proper ventilation systems [18]

Through loss trend analysis, warehouses can develop more informed approaches to equipment safety [19]. This data-driven method helps identify common hazards and guides the development of targeted safety protocols that protect both workers and valuable warehouse infrastructure.

Effective training programs stand as the cornerstone of warehouse safety, with data showing that 50% of safety incidents stem from inadequate job briefings [19]. A robust safety culture begins with comprehensive safety training that equips workers to handle workplace hazards confidently.

Safety briefings require more than just completing paperwork. Loss trend analysis reveals that only 30% of job-specific hazards get identified in typical briefings [19]. Therefore, successful warehouse programs now focus on:

Objective-Driven Approach: Training sessions explain the reasoning behind safety rules, helping workers understand why specific protocols matter [19]. This deeper understanding leads to better compliance and safer work practices.

Mentorship Programs: Experienced workers guide new hires through proper equipment usage and safety procedures [19]. This hands-on approach creates a supportive environment where newer employees feel comfortable asking questions about safety concerns.

Interactive Methods: Modern training incorporates various techniques including:

Online modules for consistent instruction

Role-playing exercises for practical experience

Gamification to boost engagement

Group discussions to share safety insights [19]

Clear visual communication proves essential for maintaining warehouse safety standards. Proper implementation of visual guides includes:

Strategic Sign Placement: Safety signage serves as constant reminders of protocols and procedures, helping prevent errors in daily operations [2]. High-contrast colors and bold fonts ensure maximum visibility, particularly in dimly lit areas.

Color-Coded Systems: Beyond OSHA's required red and yellow markings for physical hazards, warehouses benefit from comprehensive color-coding systems that improve awareness of risks. These visual cues help workers:

Identify potential hazards quickly

Locate emergency equipment

Navigate designated work zones safely

Recognize areas requiring specific PPE

Digital Displays: Modern warehouses increasingly utilize electronic job safety briefings through mobile apps [21]. These platforms offer several advantages:

Automatic task risk categorization

Access to relevant safety videos

Integration with work management systems

Quick reference to past incident lessons

Regular refresher courses ensure safety knowledge stays current [22]. Assessments verify that employees understand and can apply their training effectively. This ongoing education process includes specialized instruction for specific tasks such as forklift operation, material handling, and emergency response procedures.

Two-way communication channels enable workers to report safety concerns promptly [23]. Through mobile apps and digital platforms, employees can:

Alert supervisors to potential hazards

Request safety equipment

Share suggestions for improvements

Document near-miss incidents

Effective hazard communication is crucial for maintaining a safe work environment. This includes proper labeling of chemicals, easily accessible safety data sheets, and regular training on recognizing and handling hazardous materials.

By combining comprehensive training with clear visual guides, warehouses create an environment where safety becomes second nature rather than an afterthought. This integrated approach helps prevent accidents and possible workers' compensation lawsuits before they occur while fostering a culture of continuous safety improvement.

Establishing dedicated safety zones marks a crucial step in preventing warehouse accidents. Strategic placement of these zones, coupled with clear guidelines, helps maintain order and reduce risks in high-traffic areas.

Loading docks present unique challenges, accounting for 25% of all industrial accidents [24]. To minimize these risks, loading dock safety areas must incorporate several key elements:

Physical Barriers: Install edge guards and dock bumpers to protect against trailer separation accidents [25]. These safety measures prevent early departures, trailer creep, landing gear collapse, and trailer pop-up incidents that often result in serious injuries.

Traffic Management: Paint or tape designations mark staging areas, through aisles, and loading lanes [5]. This systematic approach helps control vehicle movement and pedestrian traffic, reducing collision risks in congested spaces.

Lighting Requirements: Mount dock-specific lights to supplement lift truck spotlights [5]. Proper illumination proves essential, as poor visibility often contributes to accidents involving moving equipment and materials.

Storage zones demand careful organization to prevent accidents involving falling objects and improper material handling. Essential safety measures include:

Barrier Protection: Safety barriers around storage areas guard valuable inventory and fragile goods from unauthorized access. These physical boundaries also protect workers from zones containing hazardous materials or automated systems.

Stack Height Control: Limit stacked material heights in staging areas where pedestrians work [5]. This precaution reduces the risk of falling objects and allows safe access for inventory inspection. Proper stacking techniques are crucial for maintaining stability and preventing collapses.

Spill Prevention: Install acid-resistant flooring in areas storing corrosive materials [6]. Additionally, maintain spill kits and neutralizing agents nearby for quick response to chemical incidents.

Ensure that storage racks are regularly inspected and maintained to prevent structural failures. Implement a system for reporting and addressing any damage or instability in racking systems promptly.

Battery charging stations require specialized safety considerations to prevent fires, explosions, and chemical exposure. OSHA mandates several key requirements [6]:

Ventilation Systems: Install adequate exhaust systems to disperse hydrogen gas released during battery charging. This prevents dangerous gas accumulation that could lead to explosions.

Emergency Equipment: Position these essential items within the charging area:

Eyewash stations within 25 feet of battery handling zones

Fire extinguishers rated for electrical fires

Personal protective equipment including face shields and rubber gloves

Neutralizing agents for electrolyte spills

Station Design: Charging installations must occupy designated areas only. These spaces should feature:

Protection from forklift damage

Proper ventilation for gassing batteries

Clear signage prohibiting smoking and open flames

Acid-resistant floors

Hoisting equipment for battery handling

Implement comprehensive fire safety measures throughout the warehouse, including regular fire drills and maintenance of fire suppression systems.

By implementing these zone-specific safety measures, warehouses create structured environments that protect workers from common hazards. Regular monitoring ensures these zones maintain their effectiveness in preventing accidents and injuries.

Warehouse safety doesn't require complex or expensive solutions. Simple changes like proper floor marking tape or floor tape, strategic lighting placement, and regular equipment maintenance significantly reduce accident risks. These basic improvements, combined with comprehensive training programs and well-designed safety zones, create a safer work environment for everyone.

Statistics show that warehouses implementing these straightforward safety measures report fewer accidents and injuries. Most notably, clear walkways, proper equipment guards, and dedicated safety zones help prevent the most common incidents - from forklift accidents to manual handling injuries.

Safety remains an ongoing commitment rather than a one-time effort. Regular assessment of workplace hazards, consistent training updates, and maintaining clear communication channels ensure these safety measures stay effective. Developing and regularly updating a warehouse safety checklist can help maintain a comprehensive approach to safety management.

Implementing an effective emergency action plan and emergency response plan is crucial for handling unforeseen situations. These plans should be regularly reviewed and practiced to ensure all employees know how to respond in case of emergencies.

Small changes today prevent major accidents tomorrow, protecting both workers and business operations. By prioritizing safety and continuously improving practices, warehouses can create a culture where safety is ingrained in every aspect of operations.

[1] - https://www.atlanticrack.com/warehouse-equipment/warehouse-safety-and-protection-equipment/[2] - https://teamdls.com/DLS-Blog/warehouse-safety-signs-labels.htm[3] - http://www.osha.gov/warehousing/hazards-solutionssrsltid=AfmBOopcCcCfZzgozGGSW5AEtgSHlr0Iqd8w3yIWujbGgzR2RmgJCNNk[4] - https://www.inboundlogistics.com/articles/warehousing-the-safety-zone/[5] - http://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.441[6] - https://www.cdph.ca.gov/Programs/CCDPHP/DEODC/OHB/HESIS/CDPH Document Library/warehous.pdf[7] - https://ohsonline.com/articles/2023/09/25/guide-for-effective-warehouse-layout-design-to-reduce-the-risk-of-accidents-and-boost-productivity.aspx[8] - https://www.paintersinc.net/blog/warehouse-safety-line-painting-guide-and-osha-floor-marking-standards[9] - https://www.hcoinnovations.com/the-impact-of-floor-markings-on-warehouse-pedestrian-safety/[10] - https://mightylinetape.com/a/blog/warehouse-safety-by-design-pt-1[11] - https://www.interlakemecalux.com/blog/warehouse-lighting[12] - https://www.ecmweb.com/lighting-control/article/21250402/warehouse-lighting-best-practices[13] - https://www.rfgen.com/blog/4-strategies-for-maximizing-warehouse-safety/[14] - https://www.shipbob.com/warehouse-management/warehouse-maintenance/[15] - https://www.axelentusa.com/world-of-axelent/knowledge/osha-guidelines-for-warehouses/[16] - https://cyzerg.com/blog/warehouse-safety-10-tips-to-keep-your-employees-safe/[17] - https://www.sme.org/technologies/articles/2024/march/improving-warehouse-safety-culture-and-safety-training-with-loss-trend-analysis1/[18] - https://www.urbint.com/blog/what-makes-an-effective-job-safety-briefing[19] - https://www.damotech.com/blog/how-to-build-a-safety-culture-in-your-warehouse[20] - https://www.regroup.com/blog/enhancing-warehouse-safety-with-mass-notification-systems/[21] - https://www.wbdg.org/space-types/loading-dock[22] - https://www.ritehite.com/en/am/news/2021/blog/5-tips-to-build-safety-into-your-loading-dock-design[23] - https://www.qmhinc.com/effective-safety-barriers/[24] - https://www.greenpowerforkliftbatteries.com/blog/understanding-forklift-battery-charging-station-safety-requirements/[25] - https://www.prolifttoyota.com/blog/forklift-battery-charging-station-safety/

https://mightylinetape.com/a/blog/category/mighty-lines-safety-talk-and-toolbox-talk-topics

https://warehousesafetytips.com/blog/