No Products in the Cart

The Art and Science of Photochemical and chemical Machining: PCM Products of Titusville, Florida In today's changing world of manufacturing and art, photochemical machining (PCM), also known as photo etching or chemical milling, stands out.

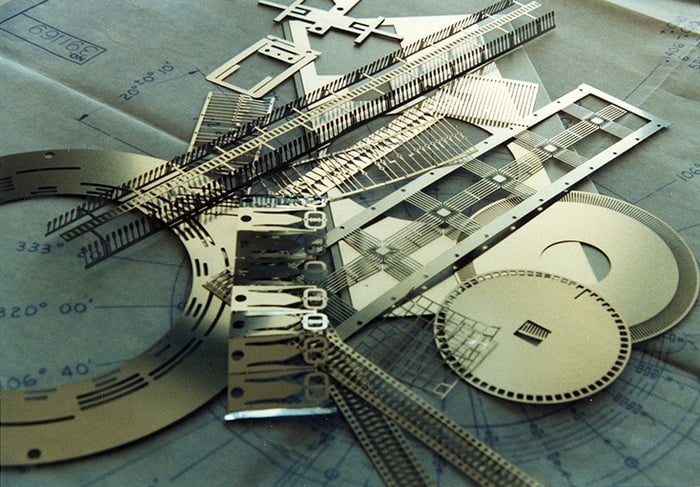

These methods have caused a revolution in making detailed parts for many industries, like aerospace, medical, and art. PCM Products Inc. (PCM company) based in Titusville, Florida, leads this new trend. Since 1969, the company has broken new ground by using these technologies to make a wide range of items, from precision components for space to artistic jewelry. This blog will look into the history, technical aspects, and uses of the photochemical etching process, while showing how PCM Products has made a big impact on the industry.

A Brief History of Photochemical Machining

Photochemical machining isn't a new idea; we can trace its beginnings to ancient cultures. The oldest types of etching show up on items from Egyptian pyramids, where craftspeople used basic techniques to carve complex patterns into metals. But the current version of photo chemical etching started in the late 1800s.

In the 1850s, photography brought new possibilities to metalworking. Eastman Kodak's breakthroughs in photo tech during the 1900s made etching more accurate. Manufacturers could now create detailed designs on metal using light-sensitive photoresist materials. This breakthrough changed everything, allowing them to produce intricate patterns and tight fits that old machining methods couldn't achieve.

How the Chemical Machining Process Works

Photo etching metal involves several main steps to etch parts precisely. Here's a simple breakdown of the photo etching process:

Material Selection: You can use different metals and alloys like titanium, tungsten, aluminum, zirconium, stainless steel, beryllium, and copper. The job's needs, including corrosion resistance, often decide which metal to pick.

Photoresist Application: A coat of light-sensitive polymer called photoresist goes on the metal surface. This layer shields parts of the metal that shouldn't be etched.

Exposure: UV light shines through a photomask with the pattern you want onto the metal coated with photoresist. The UV light makes the photoresist hard where it hits.

Development: A wash removes the soft photoresist, leaving a protective pattern on the metal surface.Etching: The chemical etchant eats away the exposed metal areas when submerged, shaping the desired features.

Final Treatment: After etching, workers strip off the leftover photoresist. The component might then go through more steps like cleaning, surface finishing, or coating.

This photochemical milling technique enables high accuracy and fine details. It works well for jobs that need tight tolerances and complex designs.

PCM Products: A History of Breakthroughs

PCM Products Inc. shows how photochemical machining can change things. Paul Richards Sr. started the PCM company in 1969. At first, it did general metal etching. But in 1977, it began to focus on photo chemical machining. Now, Paul Richards Jr. and his son run the business, keeping up the family tradition of PCM innovation and top-notch work.

What They Offer

PCM Products makes many different things using photo chemical systems. These products help many areas:

Aerospace: PCM plays a key role in aerospace, where parts must meet tough safety and performance rules. PCM Products has supplied components to the International Space Station and various satellite projects. These include cooling grids for solar panels on the Solar Probe, which travels close to the sun.

Medical Applications: Exact parts for medical implants and surgical instruments are essential to ensure healthcare tools work well. PCM's skill in making detailed components like filters, stents, pacemakers, defibrillators, and medical mesh makes them vital in this field.

Automotive Markets: PCM Products creates burr-free parts and sieves for high volume production in the automotive industry. Their precision components enable prototypes and mass manufacturing.

Artistic Uses: PCM technology isn't just for industry. It also has a place in art. Custom jewelry, complex sculptures, and decorative items show off what PCM can do in design.

Clients and Collaborations

PCM Products caters to a wide range of clients, matching the diversity of its product line. The company has built a strong reputation by tailoring solutions for customers ranging from big aerospace companies to independent artists. Paul Richards Jr. often stresses that their work goes beyond traditional limits; they meet both mechanical and artistic needs, demonstrating the adaptability of photochemical machining.

The Intersection of Art and Science

PCM's dual role in serving both artistic and scientific purposes shows how creativity and precision come together in manufacturing. This connection plays a key role in pushing technologies forward while keeping the human element that art requires.

Artistry in Precision

As we talked about, photochemical machining gives artists a chance to check out new sides of their work. They can make complex shapes and fine details, which lets them test the limits of old-school art forms. The stuff PCM Products does in this field shows how factory tech can boost artistic ideas, making pieces that might've been tough to create the usual way.

Scientific Contributions

In science and engineering, making parts with super accuracy is key. PCM Products has a big role in providing parts that meet the tough needs of aerospace and medical uses like surgical implants and orthopedic bone implants. The top-notch parts the company makes help push tech forward, leading to progress in areas like space travel and healthcare breakthroughs.

Challenges and Innovations

Despite its many benefits, photochemical machining faces industry challenges. The market goes up and down, supply chains get disrupted, and tech keeps changing, so chemical etching companies need to adapt all the time. PCM Products and others like it must stay one step ahead by putting money into R&D, checking out new materials like titanium dioxide, and making their processes better with chemical milling equipment from Chemcut and other providers.

Future Directions

Looking forward, photochemical machining has a bright future. New stuff in materials science and digital manufacturing could lead to fresh ideas. PCM Products will need to keep up their quality while embracing these new technologies. As they think about 2025 and beyond, they're still dead set on being the best, aiming to keep their family business going strong at PCM Florida and PCM Houma while getting ready for what's next. PCM InfoTech will also play a key role in driving the company's digital transformation.

Conclusion

Photochemical machining and photo etching play a crucial role in connecting art, science, and manufacturing. PCM Products Inc. in Titusville, Florida, shows how these methods can change things. The company has a long history, many different uses for its products, and always tries to do good work. This keeps PCM Inc at the top of its field. As they move forward mixing old ways with new ideas, photo chemical machining could lead to exciting new things in both art and technology. From deep space to handmade jewelry, PCM Products has an influence on many areas. This proves that machining as an art form can make amazing things.

References

https://www.pcmproducts.com/about-us/