No Products in the Cart

At Mighty Line Tape, we recognize that workplaces with clear and logical communication tend to operate more safely and efficiently. This is why we offer a variety of 5S floor tape colors and safety products that will decrease injuries and increase the overall productivity of your facility.

A Customer Review of Mighty Line floor tape and Mighty Line Floor Signs

Document your answers and create a plan for your workplace. To ensure workplace organization for years to come, conduct an annual review of your plan, and revise as needed. Mighty Line offers a wider variety of 5s Floor Tape Colors.

5S is an organization method that when properly implemented and followed can greatly improve the productivity and safety of a workplace. 5S stands for:

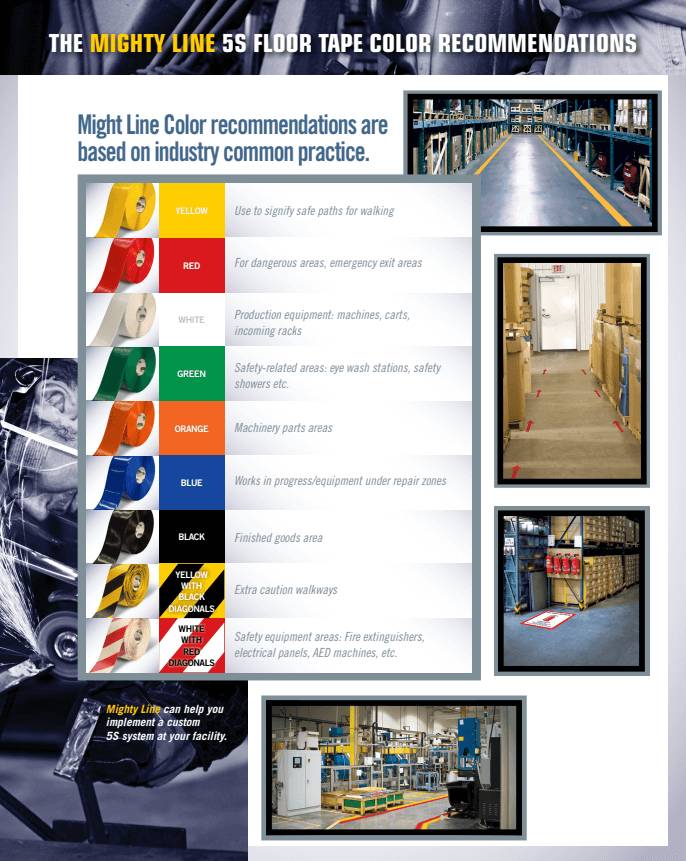

These recommendations for 5S tape colors are based on industry common practice and comply with OSHA guidelines.

In addition to 5S floor tape colors, we offer a variety of other products designed to keep your facility safe and organized. The 5S safety products we provide include:

Our safety products are commonly used in warehouses, oil and gas facilities, healthcare and hospitality environments, and a variety of other workplaces.

View our in depth floor marking tape how to guide here

Ready to improve the safety, efficiency, and profitability of your workplace? At Mighty Line Tape, we carry all the products you need to implement the 5S method at your facility. Contact us today for 5S floor tape colors or any other safety products you need.

Mighty Line 5S floor tapes are used in various settings, particularly in industrial and manufacturing environments, for several key purposes:

1- Safety: Different colors can be used to mark pathways, work cell boundaries, and hazardous areas, helping to prevent accidents and ensure worker safety.

2- Organization: The 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) aims at organizing the workplace for efficiency and effectiveness. Using different colors of floor tapes helps in distinguishing between different areas and maintaining a well-organized space.

3- Visual Management: Color-coded floor tapes and floor signs provide visual cues that guide workers, which is especially useful in large, busy environments. This helps in quick identification of areas, leading to increased productivity and reduced time in locating items or areas.

4- Compliance with Regulations: Certain industries have regulatory requirements for floor marking. Using specific colors can ensure compliance with these regulations.

5- Durability and Maintenance: Mighty Line 5S floor tapes and 5s floor signage are known for their durability and ease of maintenance, which makes them suitable for high-traffic areas.

Overall, the use of different colors in Mighty Line 5S floor tapes and floor signs are crucial for enhancing safety, efficiency, and organization in various work environments. Mighty Line 5s floor marking tape products are great for kaizen, six sigma, and TIMWOODS. This 5s Color Guide should help you pick out the 5s Colors that you need for your lean manufacturing facility. If you have any questions about Mighty Line floor tape or Mighty Line floor signs give our team at ShieldMark a call.

Helpful Links

https://issuu.com/mightylinefloortape/docs/mighty_line_osha_floor_tape_safety_color_guide

https://www.osha.gov/laws-regs/standardinterpretations/1972-05-15

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.22

https://www.serviaplogistics.com/warehouse-floor-markings/

https://www.youtube.com/watch?v=PFcs0RMsebE

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.144

https://www.asgservices.com/blog/osha-guidance-for-floor-marking-consistency/

https://www.serviaplogistics.com/warehouse-safety-floor-markings/

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.145

https://www.asgservices.com/products/osha-floor-striping-standards/

https://www.gogforce.com/columbus-oh/service/warehouse-floor-markings/