No Products in the Cart

Floor Marking Tape: A Guide to Using Mighty Line Floor Tape and Floor Signs

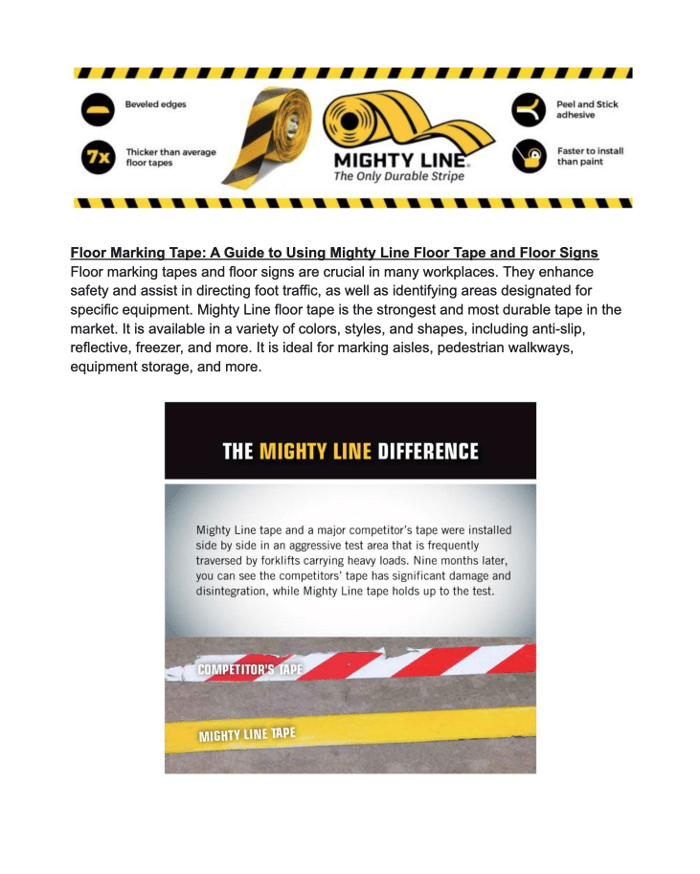

Mighty Line floor marking tape and floor signs are crucial in many workplaces. Floor marking tapes and floor signage enhance safety and assist in directing foot traffic, as well as identifying areas designated for specific equipment. Mighty Line floor tape is the strongest and most durable tape in the market. It is available in a variety of colors, styles, and shapes, including anti-slip, reflective, freezer, and more. It is ideal for marking aisles, pedestrian walkways, equipment storage, and more.

The Mighty Blueprint: A Guide to Installing Mighty Line Floor Marking Tape Products:

OSHA regulations require permanent aisles and passageways in manufacturing or storage facilities to be clearly marked. Mighty Line floor tape is the safest and easiest way to comply with these regulations while also keeping your facility organized. The tape is easy to install and remove as needed, and it can be used in various environments and situations. Here are some tips to help you install the tape and maximize its lifespan:

We always recommend testing our Mighty Line floor marking tape products on the floor before buying with our free sample kits. Concrete floors and other surfaces can vary. Request free samples here https://mightylinetape.com/pages/product-request-form

1. Prepare the Floor Surface: It is important to prepare the floor surface before installing Mighty Line floor tape. The floor must be clean and dry to ensure optimal adhesion. Avoid using acid-based cleaners that may leave residue on the floor, as they can absorb into the micropores of concrete floors and reduce the efficiency of the tape. If you must use an acid-based cleaner, neutralize the area with baking soda before applying the tape. We also offer a green, non-chlorine based all-purpose cleaner to safely and effectively clean your floors. Some floors can be cleaned with a mop and some floor could be so dirty that it needs to be cleaned with industrial scrubbers.

2. Moisture: If the tape is not sticking or releasing shortly after installation, it may be due to moisture pulling up through the floor. To test for moisture, place a 2’x2’ square of industrial stretch wrap on the ground and secure it with duct tape. If there is moisture on the stretch wrap after a few hours, there is moisture in the floor. To fix this, use a concrete sealer in the areas where you will apply the tape. We recommend using V-Seal 101 or 102 and spraying the edge of the tape after installation.

3. Oily Floors: Mighty Line floor tape may not adhere well to oily, saturated floors. If your floors are saturated with oil and grease, we recommend using an oily floor primer, such as Tri-Chem's Tri-Oil Stop. Learn more about the product here https://www.tri-chem.com/product/tri-oil-stop-oily-floor-primer/

From their website: Tri-Oil Stop is an oily floor primer for concrete prior to applying epoxy topcoats. It should be used where oil and grease have been embedded into concrete to the extent that surface cleaning is insufficient to remove it. If this goes untreated, the oil or grease may migrate back to the surface and cause de-lamination of coatings, sealers, and patching materials

4. High-Traffic Areas: In areas with heavy equipment traffic, you may want to consider using Mighty Line Dots or Segments, which can be used to create a line of easily replaceable individual dots and/or segments. You can also check out our other 5S products for similar effects and uses.

5. Miter Floor Tape Corners: You can create a professional look in your facility by mitering Mighty Line floor tape corners. Overlap the two layers of tape at the corner by a couple of inches and cut both layers together from corner to corner. Discard the excess pieces and firmly press the two cuts together to create a mitered corner.

6. Repairing or Replacing Damaged Tape: To repair or replace damaged floor tape, remove the damaged area and apply the new tape on top, overlapping the older sections. After applying, use the miter technique above to cut through both the old and new tape and remove the butt ends of each section for a clean seam.

7. Aisle Outline Width: Aisle way widths vary depending on their usage in your facility. For example, aisles used by heavy equipment will be wider than aisles used by pedestrians or workers. OSHA recommends aisle ways to be at least 3 feet wider than the largest equipment used or a minimum of 4

8. What Size Of Floor Marking Tape To Use

Mighty Line floor tape can be used in most facility work areas, and is available in tape widths of 2, 3, 4 and 6 inches. Our other 5S floor tape products also come in a variety of sizes for use throughout your facility.

9. Mighty Line Outdoors: Mighty Line isn't warranted for outside use. It can be applied outdoors however you have to be careful of snow plow and salt. We have instructions here https://issuu.com/mightylinefloortape/docs/mightylinesealerinstructions

10. Other Tips and Tricks to maintain floor tape life

Avoid Dragging skids and pallets

Avoid using heavy acids near the floor tape that could burn the adhesive

Make sure to try a free sample kit of Mighty Line to make sure it works in your environment

11. OSHA Color Code Guide:

OSHA and ANSI Z535.2 Safety Color Code help to designate colors in your workplace. For example, Yellow for Caution, Red for Danger, Orange for Warning, Green for Safety, Blue for Notice, etc. Mighty Line floor tape is also available in many other different patterns and shapes for added safety and caution.

Learn more about the OSHA guidelines here https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.144

Install Video

Why Choose Mighty Line

View our Mighty Line products catalog on our site

https://mightylinetape.com/pages/mighty-line-floor-marking-tape-product-catalog