No Products in the Cart

The festive season brings more than just carols and twinkling lights; it signals a surge in consumer activity that businesses must prepare for. From online retailers to physical stores, the holiday period often marks the busiest—and most profitable—time of the year. However, with that opportunity comes a set of challenges, making it essential to prepare warehouse for holiday demand by managing inventory, orders, and shipping efficiently.

"Christmas now surrounds us, happiness is everywhere. Our hands are busy with many tasks as carols fill the air."

🎅🌲🎁

- Shirley SallayWarehouses play a central role during this hectic period. They are the bridge between customer expectations and timely deliveries. Without proper warehouse safety measures, you risk delays, customer dissatisfaction, and missed opportunities.

A well-organized warehouse can lead to smooth operations. It can also boost productivity and improve customer satisfaction.

With more people shopping earlier, relying on quick deliveries, and expecting flawless service, the demands placed on warehouses have never been greater.

Staffing shortages, supply chain delays, and disorganized processes can compound the pressure, making it essential to plan ahead and streamline operations.

This guide offers 10 actionable strategies to prepare your warehouse for the increased holiday demand. From optimizing inventory management to improving workflows and ensuring your team is ready, these tips will help you navigate the holiday rush and maximize efficiency without compromising quality.

The holidays are coming—let’s get your warehouse ready.

An accurate inventory is critical as you prepare warehouse for holiday demand, ensuring you meet customer expectations seamlessly. Without a clear picture of your stock levels, you risk overselling popular items, delaying fulfillment, or disappointing customers with backorders.

A pre-holiday inventory audit ensures you know exactly what you have, what you need, and where everything is located—making it one of the most effective inventory management tips for the holiday season.

Avoid Stockouts: Running out of best-selling products can lead to missed opportunities and frustrated customers.

Prevent Overstocking: Excess stock ties up capital and clutters your warehouse, reducing efficiency.

Streamline Fulfillment: Knowing precise inventory locations speeds up picking and packing, which is crucial for meeting delivery timelines.

Improve Forecasting: A clean inventory helps you identify trends and predict demand more accurately for the season ahead.

Start Early: Conduct your inventory audit well before the peak holiday period to leave room for adjustments.

Prioritize High-Demand Items: Identify best-sellers or seasonal products that are likely to move quickly. Confirm their availability and reorder if stock is low.

Categorize and Label: Organize products into clear categories and ensure everything is accurately labeled with barcodes or tags to minimize picking errors.

Verify Inventory Records: Cross-check your physical stock with your warehouse management system (WMS) or inventory software to identify discrepancies.

Adopt Cycle Counting: For larger warehouses, focus on high-value or fast-moving items first instead of auditing everything at once.

Declutter and Reorganize: Remove obsolete or slow-moving items to free up space for holiday inventory.

Update Technology: If you’re still relying on manual counts, consider upgrading to automated systems or RFID tracking for improved accuracy and efficiency.

By conducting a thorough inventory audit, you can eliminate surprises, reduce fulfillment errors, and keep operations running smoothly when the pressure is on. This proactive step sets the foundation for a stress-free, high-performing holiday season.

An efficient warehouse layout is the cornerstone of smooth operations, particularly during the holiday season when every second counts. Strategically rearranging your space is an essential step to prepare warehouse for holiday demand, minimizing delays, and maximizing productivity. Optimizing your layout ensures high-demand items are accessible and workflows are seamless, keeping up with customer expectations.

Streamline Picking Paths: Organize stock in a logical sequence that minimizes backtracking. Use a serpentine or U-shaped layout to guide pickers efficiently.

Separate Work Zones: Dedicate areas for picking, packing, and shipping to avoid bottlenecks during peak hours.

Label Clearly: Ensure aisles, racks, and storage areas are clearly marked to prevent confusion and reduce search time.

To truly optimize your layout, visual guides like floor marking tape can make a significant difference. Mighty Line Tape offers customizable solutions for:

Defining Work Zones: Use durable floor tape to mark areas for picking, packing, and equipment storage.

Highlighting Safety Paths: Ensure forklifts and workers navigate the warehouse safely with high-visibility aisle markings.

Quick Layout Adjustments: With Mighty Line’s peel-and-stick technology, reconfiguring zones for holiday demands is hassle-free.

By rearranging your layout and leveraging tools like high-visibility warehouse markings simplify zone separation, making operations faster and safer during busy periods. A well-organized warehouse isn’t just functional—it’s a competitive advantage during the holiday rush.

The holiday season brings a heightened level of activity that requires a prepared and well-trained team. Whether it’s your regular workforce or temporary hires, effective training ensures everyone understands their roles, workflows are seamless, and errors are minimized.

Investing in seasonal workforce training not only ensures efficiency but also builds confidence among temporary hires.

Enhanced Efficiency: Trained staff can adapt to increased demands and operate equipment or systems with confidence.

Reduced Errors: Proper training minimizes mistakes in picking, packing, and shipping, which are crucial to meeting customer expectations.

Team Morale: A well-prepared team is less stressed and more motivated, leading to higher productivity and job satisfaction.

Start Early: Begin recruiting and onboarding temporary staff weeks before the holiday rush. This gives them time to familiarize themselves with the processes.

Provide Hands-On Training: Pair temporary hires with experienced team members for shadowing and hands-on practice to learn warehouse operations quickly.

Create Clear Training Materials: Use checklists, manuals, or videos to explain warehouse workflows, safety protocols, and common challenges.

Focus on Key Skills: Train temporary staff specifically on high-priority tasks, such as picking, packing, or equipment usage, to maximize their effectiveness.

Highlight Safety Procedures: Ensure every team member, including seasonal workers, is well-versed in safety protocols to prevent accidents in a busier-than-usual environment.

Use Simulations: Run practice drills for high-pressure situations, such as handling bulk orders or resolving inventory discrepancies, to prepare staff for real-time challenges.

A prepared team is the backbone of a successful peak season. By equipping your regular staff with refresher training and onboarding temporary hires effectively, you can maintain smooth operations and keep up with demand. Remember, your team’s confidence and readiness directly impact your warehouse’s ability to meet customer expectations.

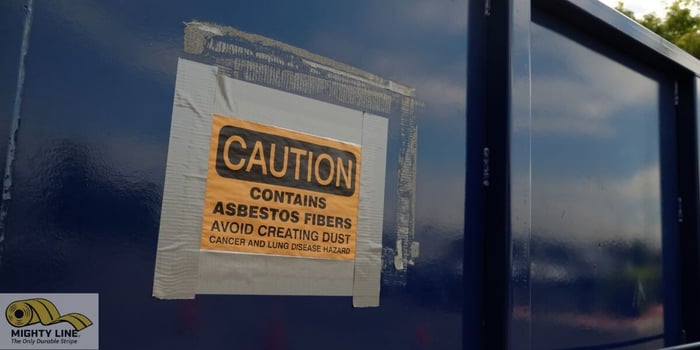

The holiday rush means higher volumes of workers, equipment, and activity in your warehouse, creating a greater risk of accidents. Establishing and enforcing safety measures is essential to protect your team, maintain productivity, and ensure operations run smoothly. A safe environment during peak periods is not only a legal obligation but also a morale booster that shows employees their well-being is a priority.

Designated Walkways: Clearly mark pedestrian pathways to separate foot traffic from equipment zones, reducing the risk of collisions.

Traffic Flow Management: Establish one-way aisles and enforce speed limits for forklifts and carts to minimize congestion and accidents.

Proper Equipment Use: Train all staff—both permanent and temporary—on the correct operation of equipment like forklifts, conveyors, and ladders.

Adequate Lighting: Ensure all work areas are well-lit, especially around high-traffic zones and storage racks.

Daily Safety Inspections: Regularly check for hazards such as spills, obstructions, or damaged equipment, and address them immediately.

Mighty Line’s anti-slip tape helps keep people safe. It is a smart way to stop slips and falls in busy areas. Key benefits include:

Durability: Designed to withstand heavy foot traffic and machinery, making it ideal for busy warehouse floors.

High Visibility: Available in bright colors to improve visibility and guide workers safely.

Quick Installation: Peel-and-stick application allows you to address safety concerns promptly, even during peak periods.

Versatility: Use anti-slip tape on stairs, ramps, and other slippery surfaces to create a safer workspace for everyone.

Safety is everyone’s responsibility, but it starts with clear protocols and accessible tools. By combining proactive warehouse safety measures with Mighty Line’s solutions, you can foster a secure environment during peak periods.

Clear signage and accurate labels are essential for maintaining efficiency and organization during the holiday rush. In a busy warehouse, where time is of the essence, easily identifiable signs and labels ensure workers can locate items, follow processes, and maintain safety without unnecessary delays. Upgraded signage and labels enhance visual communication in warehouses, helping workers navigate efficiently and reducing errors.

Speed Up Processes: Workers can quickly locate inventory, equipment, and workstations, saving valuable time.

Minimize Errors: Clear labeling reduces the chances of picking the wrong items or misplacing inventory.

Improve Safety: Well-placed signs and labels highlight hazards, traffic flow, and emergency exits, ensuring everyone stays safe.

Support New Staff: Temporary workers can navigate the warehouse confidently with well-marked areas and clear instructions.

Use High-Contrast Colors: Opt for bold, high-contrast colors to ensure signs and labels are easy to read from a distance.

Standardize Label Formats: Adopt a consistent format for labels, including clear font sizes and concise information like SKU numbers or product names.

Place Signs Strategically: Position signs at eye level and in high-traffic areas for maximum visibility.

Incorporate Barcodes or QR Codes: Upgrade labels to include protected scannable codes, making inventory tracking faster and more accurate.

Regular Maintenance: Inspect and replace worn or damaged signs and labels to keep everything legible and effective.

Mighty Line’s high-visibility floor tape is an invaluable tool for upgrading your warehouse signage. Key features include:

Clear Demarcation: Mark aisles, storage zones, and safety areas with bold, bright colors that stand out.

Customizable Options: Choose from various patterns, widths, and messages to suit your specific needs.

Durability: Designed to withstand heavy traffic and harsh environments, ensuring your markings stay intact during peak periods.

Easy Application: Peel-and-stick technology allows for quick installation, even in a bustling warehouse.

By upgrading signage and labels with tools like Mighty Line’s high-visibility floor tape, you can create a more organized, efficient, and safer warehouse environment. Clear visual guidance not only enhances productivity but also builds confidence among your team as they navigate the holiday rush.

Well-maintained equipment is critical for smooth warehouse operations, especially during the holiday season when demand peaks. Equipment breakdowns during this period can lead to costly delays, bottlenecks, and safety risks. Follow the equipment maintenance checklist to ensure your machinery is reliable and efficient during the holiday rush.

Prevent Downtime: Avoid unexpected breakdowns that can disrupt operations during the busiest time of the year.

Ensure Safety: Properly maintained equipment minimizes risks of accidents and injuries.

Maximize Efficiency: Equipment in peak condition operates faster and more accurately, boosting productivity.

Inspect Critical Machinery: Examine forklifts, conveyor belts, pallet jacks, and packing machines for wear and tear.

Check Moving Parts: Lubricate hinges, gears, and other moving components to ensure smooth operation.

Test Safety Features: Verify that safety mechanisms, such as emergency stops and alarms, are functioning correctly.

Calibrate the equipment: Ensure that you calibrate weighing scales, scanners, and automated systems for accuracy.

Replace Worn Parts: Stock up on spare parts like belts, tires, and filters to quickly replace damaged components.

Clean and Debris-Free: Remove dust, grease, and debris that can clog or damage machinery.

Battery Maintenance: For battery-powered tools, make sure to fully charge the batteries. Check that the connections are secure. Always have backup batteries ready.

Schedule Professional Servicing: If necessary, bring in certified technicians to perform thorough maintenance or repairs.

Document Maintenance: Keep records of all inspections and repairs to track equipment history and ensure compliance with safety standards.

Test Equipment Post-Maintenance: After servicing, test each piece of equipment to confirm it’s operating as expected.

By scheduling and performing equipment maintenance ahead of the holiday rush, you can reduce the likelihood of disruptions, improve safety, and maintain efficiency. A little preparation now can save significant time, money, and stress when it matters most.

Even with thorough preparation, unexpected disruptions can arise during the holiday season. From supply chain delays to equipment malfunctions and staffing shortages, having a well-thought-out contingency plan ensures your warehouse can adapt quickly and minimize downtime. Proactive planning is key to holiday logistics optimization, helping you adapt to unexpected challenges without compromising service.

Reduce Downtime: Quickly address disruptions to prevent delays in order fulfillment.

Mitigate Risks: Anticipate and minimize the impact of common holiday challenges.

Maintain Customer Satisfaction: Ensuring consistent service during disruptions strengthens your brand reputation.

Identify Potential Risks: Conduct a risk assessment to pinpoint common issues such as inventory shortages, power outages, or software failures.

Build a Backup Inventory: Stockpile high-demand items and essential supplies to prevent delays due to supply chain interruptions.

Cross-Train Employees: Train staff in multiple roles so they can step in if colleagues are unavailable or workloads increase unexpectedly.

Secure Backup Equipment: Keep spare equipment or rental options on hand for critical machinery like forklifts or conveyors.

Establish Emergency Contacts: Create a list of key suppliers, technicians, and service providers who can respond promptly to emergencies.

Develop a Communication Plan: Ensure clear lines of communication for notifying staff, suppliers, and customers about potential delays or adjustments.

Test Your Plan: Run simulations or drills to identify weaknesses in your contingency plan and refine it before the holiday rush.

A robust contingency plan empowers your team to navigate disruptions confidently and efficiently. By anticipating challenges and preparing solutions in advance, your warehouse can maintain high performance and deliver exceptional service—even under pressure.

During the holiday rush, packing and shipping are the final, critical steps in your warehouse workflow. Efficiency in these areas ensures orders are fulfilled quickly and accurately, meeting tight deadlines and exceeding customer expectations. By organizing and streamlining these zones, you can eliminate bottlenecks, reduce errors, and keep operations running smoothly.

Designate Specific Areas: Separate packing and shipping zones to prevent confusion and allow each process to operate independently.

Optimize Space: Arrange tables, equipment, and supplies to ensure workers have everything they need within easy reach.

Standardize Packing Stations: Equip each station with the same tools and materials, such as tape, boxes, and labels, to maintain consistency and speed.

Implement Batch Processing: Group similar orders together to streamline packing and reduce handling time.

Use Technology: Incorporate scanning systems and label printers to speed up processing and improve accuracy.

Monitor Workflow: Assign team leaders to oversee packing and shipping areas, quickly addressing any bottlenecks or issues.

Mighty Line floor markings are an effective solution for organizing and optimizing your packing and shipping areas. Here’s how they help:

Clear Zone Separation: Use floor tape to define specific areas for packing, shipping, and staging, ensuring smooth workflows.

Improved Safety: Mark pathways and keep high-traffic zones distinct to avoid accidents during busy periods.

Customizable Options: Choose colors, patterns, and messages that suit your warehouse’s unique needs.

Durable and Easy to Apply: Durable floor marking tape from Mighty Line is ideal for defining zones, improving efficiency, and maintaining safety during the holiday rush.

Streamlined packing and shipping areas are essential for maintaining productivity and accuracy during the holiday season. By organizing these zones and incorporating tools like Mighty Line floor markings, you can improve workflows, reduce errors, and ensure orders are shipped on time, every time.

In a bustling warehouse, efficient traffic flow is key to maintaining productivity and safety during peak seasons. Poorly managed movement of personnel and equipment can lead to delays, congestion, and accidents, disrupting operations when time is of the essence. Monitoring and optimizing traffic flow ensures a smoother workflow, minimizing interruptions and maximizing efficiency.

Map Out Traffic Patterns: Analyze how workers and equipment move through the warehouse to identify areas of congestion or inefficiency.

Establish One-Way Aisles: Use directional paths to reduce bottlenecks and prevent collisions in high-traffic areas.

Designate Specific Lanes: Separate lanes for forklifts, carts, and foot traffic to keep movement orderly and reduce the risk of accidents.

Schedule Movement Strategically: Stagger equipment use during peak hours to prevent overcrowding in key areas.

Implement Traffic Control Measures: Use signs, floor markings, and barriers to guide personnel and equipment efficiently through the warehouse.

Monitor in Real Time: Deploy supervisors or install sensors and cameras to oversee traffic flow and address issues promptly.

Traffic flow isn’t static; as your operations scale for the holiday season, the layout and movement patterns may need to be adjusted. Regular monitoring and feedback from your team can help you identify new bottlenecks or inefficiencies and adapt your strategy accordingly.

By proactively managing traffic flow, your warehouse can handle the increased holiday demand with fewer delays and a safer environment. Implementing traffic flow solutions like one-way aisles and separate lanes for equipment reduces congestion and improves efficiency.

Success during the holiday rush doesn’t just come from preparation—it also comes from reflection. Reviewing data from previous holiday seasons provides valuable insights into what worked, what didn’t, and where improvements can be made. By analyzing historical performance, you can refine your strategies and create a roadmap for a more efficient and successful operation.

Identify Trends: Understand which products sold the most, when demand peaked, and how your resources were utilized.

Spot Bottlenecks: Pinpoint recurring issues, such as delays in specific processes or areas, and address them proactively.

Evaluate Team Performance: Assess how staffing levels and productivity measured up to the holiday demand.

Improve Forecasting: Use data to predict inventory needs, order volumes, and resource allocation for the upcoming season.

Collect Key Metrics: Gather data on sales volumes, order fulfillment times, inventory turnover, and error rates from previous years.

Analyze Order Patterns: Look for spikes in demand, commonly purchased items, and any seasonal fluctuations that impacted operations.

Evaluate Customer Feedback: Review customer reviews and support tickets to identify areas where service exceeded expectations—or fell short.

Involve Your Team: Hold debrief sessions with staff to discuss operational challenges and gather suggestions for improvement.

Set Benchmarks: Use insights to establish performance goals and KPIs (key performance indicators) for the upcoming season.

Document Lessons Learned: Create a comprehensive report of findings and recommendations for future reference.

Analyzing past data allows for better holiday logistics optimization, helping you refine strategies and improve efficiency. By learning from past successes and challenges, you can anticipate obstacles, replicate achievements, and ensure a smoother operation for the next holiday rush.

The holiday season is an exciting yet demanding time for warehouses. By implementing the strategies outlined in this guide—auditing your inventory, optimizing your layout, training your team, and enhancing safety measures—you can effectively prepare warehouse for holiday demand and meet customer needs. Now, you are ready to tackle the busiest time of the year!

Proactive planning, continuous monitoring, and leveraging the right tools are the keys to keeping operations smooth and customers happy.

One essential tool to consider is Mighty Line Tape. With customizable, durable, and high-visibility solutions, Mighty Line Tape can help you streamline workflows, define zones, and enhance safety in your warehouse. Whether it’s marking pathways, separating workstations, or preventing slips and falls,

Mighty Line products provide the versatility and durability you need to stay ahead of the holiday rush.

Don’t wait until the last minute—start preparing now and let Mighty Line Tape help you create a warehouse that runs like clockwork. Explore their range of products to optimize your space and ensure your operations are set up for success.

Visit Mighty Line's floor sign collections today and gear up for your best holiday season yet!