Cost-Benefit Analysis of Heavy-Duty Tape vs. Paint vs. Projectors

In industrial settings, effective floor marking tape is essential for safety and organization. Choosing the right solution can be challenging with options like heavy-duty tape, paint, and projectors. Each has unique benefits and costs, but which one offers the best value? This article compares these solutions, providing a clear cost-benefit analysis to help you make an informed decision. By the end, you'll understand why Mighty Line heavy duty floor marking tape often emerges as the superior choice for industrial floor tape needs.

Overview of Floor Marking Solutions

Choosing the right floor marking tape solution is crucial for maintaining safety and efficiency in industrial environments. Let's look deeper into each option, highlighting their unique characteristics and practical applications.

- Heavy-duty tape: A reliable and versatile choice for industrial floor marking. Its ease of application and robust performance make it the best tape for floor marking in many facilities. In a busy warehouse, using heavy duty floor tape like Mighty Line tape to mark pathways and storage areas can streamline operations and reduce accidents. The durability of this factory floor tape ensures it remains intact despite the constant movement of heavy machinery and pallets.

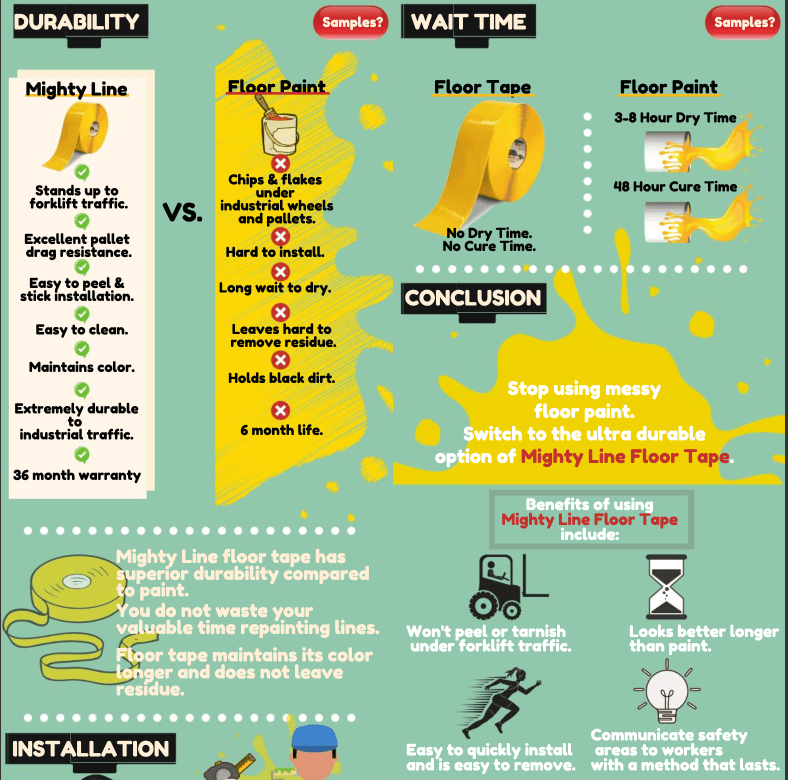

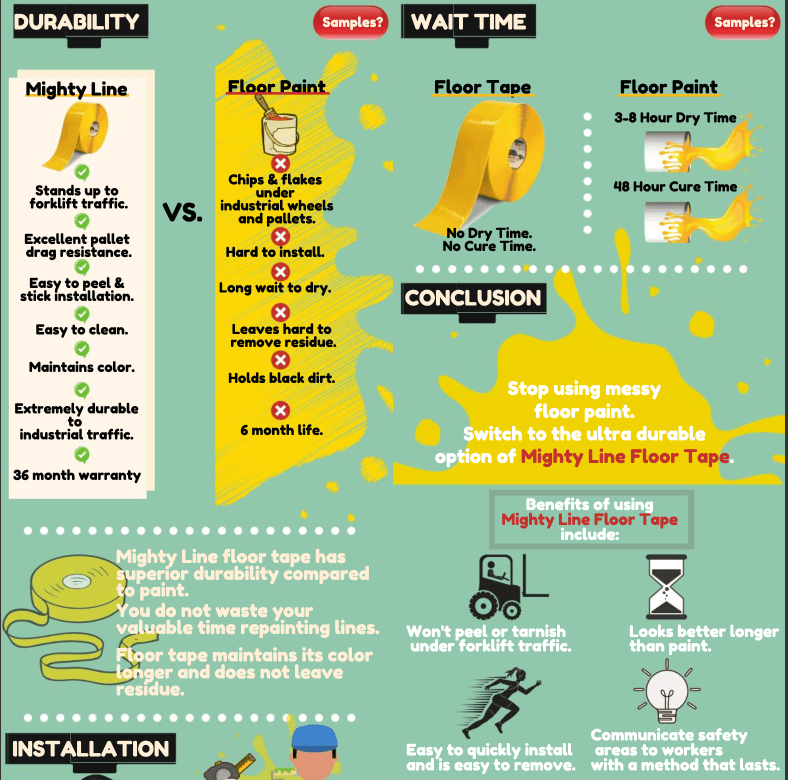

- Paint: A common method for floor striping, particularly in older facilities or those with large open spaces. A manufacturing plant using paint for floor marking may find that the lines fade quickly due to constant foot and machinery traffic. This requires periodic shutdowns for repainting, affecting overall productivity.

- Projectors: A high-tech solution for floor marking by projecting virtual lines and signs onto surfaces. In a logistics hub, projectors might be used to display dynamic information, such as temporary pathways or hazard warnings. However, a power outage during peak operations could lead to confusion and safety risks, highlighting the importance of a reliable power supply.

By understanding the benefits and drawbacks of each floor marking tape solution, industrial facilities can make informed decisions that balance cost, durability, and practicality. In the next sections, we will explore a detailed cost analysis and benefit analysis to further aid this decision-making process.

Cost Analysis

Let's break down the costs associated with heavy duty tape, paint, and projectors by examining initial costs, maintenance, and long-term expenses.

Initial Costs

Initial costs encompass the purchase price and installation expenses, which can vary significantly among the three options.

- Heavy-Duty Tape: Heavy-duty tape like Mighty Line Floor Tape offers a cost-effective solution, reflecting its high quality and durability. The easy installation is straightforward and quick, requiring minimal labor. This translates to lower overall initial costs since downtime is negligible. In a warehouse setting, installing heavy duty vinyl tape over a weekend can be accomplished without disrupting operations, keeping the facility running smoothly.

- Paint: Paint is relatively inexpensive, making it a popular choice for budget-conscious operations. Despite its low purchase price, the labor involved in applying paint, including surface preparation, masking, multiple coats, and drying time, can significantly increase the initial costs. Downtime during the painting process adds to the expense. A manufacturing plant might find that while the paint itself is cheap, the cost of halting production for a day to allow the paint to dry can be substantial.

- Projectors: Projectors have a high upfront cost, around $1,450 for a single unit. Installation requires skilled labor to ensure correct placement and calibration, adding to the initial expense. A logistics center installing projectors must factor in the cost of professional installation, which can quickly escalate, especially if multiple units are required.

Longevity and Maintenance Costs

Maintenance costs are ongoing expenses that must be considered to understand the true cost of each solution over time.

- Heavy-Duty Tape: Heavy-duty tape like Mighty Line Floor Tape is designed for long-term use, with minimal need for replacements. Its durability in high-traffic areas reduces maintenance costs significantly. A distribution center using this durable floor tape may only need to replace sections every few years, keeping maintenance costs low.

- Paint: Painted lines wear out quickly, especially in high-traffic areas. This necessitates frequent touch-ups and complete reapplications, leading to higher maintenance costs over time. A factory floor that experiences heavy machinery traffic might need to repaint its lines every six months, leading to recurrent labor and material costs.

- Projectors: Projectors require regular bulb replacements, which can be costly. Additionally, their dependence on a continuous power supply means they incur ongoing energy costs. In a large warehouse, the need to replace projector bulbs regularly and the constant electricity usage can add up, making projectors expensive to maintain.

Hypothetical Cost Comparison

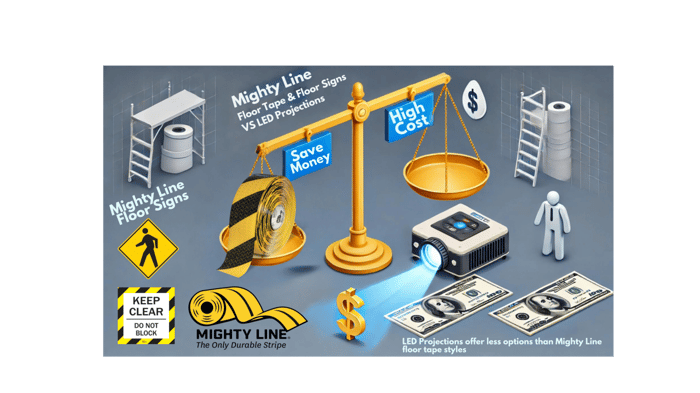

Virtual Sign Projectors VS Heavy Duty Floor Signs

When comparing the costs of, a clear picture of the financial implications emerges. Virtual Sign Projectors come with an estimated cost of $950.00 each, and installation costs add another $500.00, bringing the total cost per projector to $1,450.00. For outfitting ten locations, this adds up to a hefty $14,500.00. Mighty Line Heavy Duty Floor Signs, on the other hand, are priced at $39.99 per sign.

For the price of one projector, you can purchase 36 signs, totaling $1,439.64. For ten locations, assuming one sign per location, the total cost stands at a mere $399.90. When considering usage estimates, high-traffic areas require 1 to 2 signs per year, while low-traffic areas need one sign every 3 to 5 years, making the floor signs a cost-effective solution over time.

Installing 100 Feet of Line: Virtual Line Projectors VS Line Floor Tape

Virtual Line Projectors cost $1,299.99 for a projector that can display 48 feet of line. With an additional $500 installation fee, the total comes to $1,799.99. Installing 100 feet of lines requires two projectors and two installations, totaling $3,599.98.

Mighty Line Floor Tape costs $162.33 for a 4-inch wide, 100-foot long roll. Installation is approximately $1 per foot, adding $100 for 100 feet, making the total $262.33. For the price of one projector, you could purchase nearly 14 rolls of this line marking tape. Overall, Mighty Line products offer a significantly lower cost alternative to Virtual Sign Projectors, both in initial expenses and ongoing maintenance, making them a more economical choice for most applications.

By examining initial, maintenance, and long-term costs, it becomes evident that heavy duty tape often provides the best value for industrial floor marking. Its balance of upfront cost, durability, and low maintenance needs makes it a cost-effective solution compared to paint and projectors. Next, we will explore the benefits of each solution to further clarify which option best meets your facility's needs.

Here is a simple chart comparing the costs of LED Projectors and Mighty Line for a 100' setup:

Benefit Analysis

A thorough benefit analysis reveals how each floor marking tape solution performs in real-world scenarios. Understanding these benefits helps determine which option provides the best long-term value and functionality.

Durability and Longevity

Durability and longevity are crucial factors when choosing a floor marking tape solution. The ability to withstand daily wear and tear ensures that markings remain effective and visible.

Heavy-Duty Tape:

- Thick and Resistant: Heavy-duty tape is designed to endure heavy forklift traffic, including forklifts and industrial machinery rolling on top. Its 50 mil thickness and material composition provide excellent resistance to wheel abrasion. In a distribution center, where forklifts constantly move pallets, heavy duty floor tape remains intact, maintaining clear pathways and safety zones. Mighty Line has a 3-year warranty on its floor tape. The main thing that nullifies this warranty is dragging skids directly on top or pushing and pulling skids

Paint:

- Wears Out Quickly: Painted lines deteriorate rapidly in high-traffic areas. The continuous movement of equipment and foot traffic causes paint to chip and fade, necessitating frequent touch-ups. A manufacturing plant might need to repaint safety lines every six months due to the heavy movement of machinery, leading to regular disruptions.

Projectors:

- Depend on Power: Projected markings are vulnerable to power outages and require constant electricity. Additionally, physical obstructions can block the projected image, reducing visibility. In a large warehouse, a power outage could render all floor markings invisible, causing confusion and potential safety hazards.

Ease of Application and Flexibility

The ease of application and flexibility of floor marking tape solutions can significantly impact operational efficiency and downtime.

Mighty Line Heavy-Duty Tape:

- Easy to Apply and Remove: The peel-and-stick design allows for quick and clean application. Removing or repositioning the tape is straightforward, making it ideal for dynamic work environments.

- Minimal Downtime: Installation can be done without major disruptions, allowing for continuous operation. In a logistics hub, reconfiguring the layout is simple with heavy-duty tape, enabling quick adjustments to meet changing needs.

Paint:

- Significant Downtime: Painting requires substantial preparation and drying time, leading to operational interruptions. The need for multiple coats and proper ventilation further complicates the process. A factory floor might need to shut down for an entire day to allow freshly painted lines to dry, resulting in lost productivity.

Projectors:

- Complex Installation: Setting up projectors requires precise placement and calibration, which can be time-consuming. However, once installed, they are easy to reconfigure with simple adjustments. In a tech-driven warehouse, changing the layout involves reprogramming the projectors, allowing for quick updates to floor markings.

Customization and Visibility

Customization and visibility are essential for effective floor marking, ensuring that markings are clear and tailored to specific needs.

Heavy-Duty Floor Tape:

- Wide Range of Options: Available in various colors, patterns, and shapes, heavy-duty tape can be customized to fit any industrial requirement. This includes adding text, logos, and specific designs.

- High Visibility: The vivid colors and patterns ensure that markings are easily seen, enhancing safety and organization. A healthcare facility uses customized heavy-duty tape to mark emergency pathways and equipment zones, ensuring clear guidance in critical situations.

Paint:

- Limited Customization: Paint offers fewer customization options and is generally restricted to standard colors and simple patterns. Complex designs are difficult to achieve and maintain. A retail store may use painted lines for basic aisle marking but finds it challenging to incorporate detailed safety signs.

LED Projectors:

- Limited Color Options: While projectors can display bright images, their color options are limited. Visibility can be compromised by physical obstructions. In a busy airport, projected lines might be blocked by luggage carts and passengers, reducing their effectiveness.

By examining the benefits and real-world applications of each floor marking solution, it's clear that heavy-duty tape offers the best combination of durability, flexibility, and cost-effectiveness. Now, let's explore how sustainability and long-term environmental considerations play a role in choosing the right marking method.

How Durable is it

How robust and heavy duty are the floor marking tapes should be considerations that are increasingly important in today's industrial practices.

Mighty Line Heavy-Duty Tape:

- Heavy Duty Materials: Mighty Line heavy-duty tapes are made from heavy duty industrial materials, reducing their the amount of floor tape and how often it need replaces. Mighty Line floor tapes have beveled edges. Their long lifespan also means less frequent replacements, contributing to sustainability.

Paint:

- VOC Emissions: Traditional paints emit volatile organic compounds (VOCs), which are harmful to the environment and human health. The application process also generates waste from cleaning and excess materials. A food processing facility might need to consider the impact of VOC emissions on air quality and product safety.

Projectors:

- High Energy Consumption: Projectors require significant energy to operate continuously, contributing to higher carbon footprints. Additionally, they generate electronic waste from bulb replacements and eventual disposal. A data center might face increased energy costs and environmental impact due to the continuous operation of projectors.

Considering the environmental impact of floor marking solutions provides a broader perspective on their sustainability. Now, let's focus on why Mighty Line's heavy-duty tape stands out as the preferred choice for many industrial applications.

Why Choose Mighty Line Heavy-Duty Tape?

Mighty Line's heavy-duty tape stands out as a cost-effective, durable, and environmentally friendly solution for industrial floor marking.

- Cost-Effectiveness: Heavy-duty tape offers significant cost savings over time compared to paint and projectors. Its lower long-term costs result from minimal maintenance and infrequent replacements.

- Durability and Performance: Proven to withstand the rigors of industrial use, Mighty Line's heavy-duty tape maintains its integrity and visibility in high-traffic environments.

- Customization and Versatility: With a wide range of options, Mighty Line's tape can be customized to meet specific needs, from standard safety markings to complex organizational designs.

- Easy Application and Minimal Downtime: The quick installation process ensures minimal disruption to operations, allowing businesses to maintain productivity.

- Customer Satisfaction and Warranty: Mighty Line offers a three-year limited warranty, reflecting their confidence in the durability and performance of their products. Positive feedback from users highlights the reliability and quality of Mighty Line's tape.

When evaluating the costs and benefits of heavy-duty tape, paint, and projectors, the numbers favor heavy-duty tape. It combines durability, ease of use, and cost-effectiveness, making it the best choice for industrial floor marking. Mighty Line's products provide the reliability and performance needed to maintain safety and organization in industrial settings.

Ready to make the smartest choice for your industrial floor marking needs? Contact us today to learn more about Mighty Line's heavy-duty tape solutions and discover how they can enhance your facility's safety, efficiency, and sustainability. Don't wait—transform your workspace with the best in the industry!

FAQs

- Mighty Line industrial floor marking tape is made in the USA from a veteran owned small family business and one of the reasons its one of leading marking tape manufacturers.

- Mighty Line floor tape's most popular product is the floor yellow tape. However it's diagonal are one of the most durable hazard diagonal floor tapes in the market.

- Mighty Line is a heavy duty double sided tape that has a top vinyl side for use a floor striping tape and warehouse marking tape.

- Mighty line has been improving workplace safety and improving visual communication for almost 20 years in the market and for use a floor tape for warehouse.

- Mighty line is the leading heavy duty warehouse floor tape in the market because of its industrial strength and the variety of colors to use as a 5s floor tape.

- Mighty Line offers anti-slip tape, reflective tape, safety floor tape, glow-in-the-dark tape, 5s floor markings and a variety of stocked safety floor signs.

- Mighty Line floor marking tapes help OSHA compliance, mark traffic lanes, improve traffic flow, hazard identification with its color-coded tape.

- Mighty Line leaves no residue or minimal residue after years of use on the concrete floor.

References

https://www.youtube.com/watch?v=DUqm5XauB_Q

https://mightylinetape.com/a/blog/paint-vs-tape-why-mighty-line-floor-tape-is-the-superior-choice-for-warehouse-floor-marking

https://www.floortapestore.com/pages/cost-justify-mighty-line-vs-painting

https://mightylinetape.com/pages/frequently-asked-questions-mighty-line-floor-tape#:~:text=Mighty%20Line's%20floor%20marking%20tape%20is%20easier%20to%20install%2C%20more,is%20time%20to%20redo%20lines.

https://mightylinetape.com/a/blog/mighty-line-floor-marking-tape

https://mightylinetape.com/a/blog/understanding-ansi-codes-an-in-depth-guide-to-ansi-z5351-color-standards

https://mightylinetape.com/a/blog/oshas-safety-colors-guide-mighty-line-minute-ep-11

https://www.mightylineminute.com/

https://mightyline.ctcin.bio/

https://warehousesafetysolutions.co.uk/blogs/news-1/the-pros-cons-of-adhesive-floor-marking-tape-vs-floor-marking-paint

https://kyleschmoyer.com/