No Products in the Cart

Today's logistics landscape requires efficiency and organization to be successful. One of the things business owners use to achieve these goals is floor marking tapes. While typically used for safety or directional purposes, its versatility extends beyond traditional applications.

In this article, let's take a closer look at the innovative ways floor marking tapes can revolutionize the organization of shipping and receiving zones. Read this now as we provide you with creative uses to optimize operations and contribute to a safer and more organized work environment.

● Commonly connected with safety or directional purposes, floor marking tapes provide unique options for optimizing designated shipping and receiving areas.

● From designating boundaries to creating clear pathways and marking storage locations, floor marking tapes are crucial in streamlining operations and promoting safety within shipping and receiving areas.

● Businesses may enhance their shipping processes by emphasizing organization and properly using floor marking tapes, resulting in smoother operations and a safer work environment.

Floor marking tapes are adhesive tapes explicitly used for marking out areas on floors. They are usually made from durable materials such as vinyl or polyester, ensuring longevity and wear and tear resistance from foot traffic and machinery. These tapes come in various colours, patterns, and sizes, allowing customization to suit different purposes and environments.

Floor tapes have versatile uses when it comes to warehouse management systems. Let's get to know some of them and their uses in this portion.

Yellow floor tapes are used to mark boundaries, designate specific areas for the shipping and receiving area or highlight potential hazards in the warehouse. Their bright yellow colour ensures high visibility, making them practical tools for indicating safe walking paths, delineating work zones, or marking locations of emergency and other equipment.

Additionally, they can serve as visual cues for maintaining cleanliness and organization, aiding in the efficient management of space and workflow within the shipping facility.

Black and yellow striped floor marking tapes are designed for safety and hazard communication in shipping areas. The distinctive black and yellow stripes create a highly visible pattern that warns individuals of potential dangers or restrictions in the designated place.

Commonly used to highlight hazards such as low clearance areas, uneven surfaces, or areas with moving equipment, these tapes serve as visual cues to prevent accidents in premises and promote operational efficiency and workplace safety.

Red floor marking tapes help ensure quick and easy identification during emergencies, allowing for quick response and ensuring the safety of occupants within the shipping area. Universally recognized as a warning sign, red marking tapes effectively draw attention to hazards such as fire exits, firefighting equipment, or electrical panels.

Additionally, they can be used to mark specific zones for fire prevention measures, such as keeping flammable materials away from ignition sources, contributing to overall workplace safety and maximum efficiency following quality control standards.

Blue floor marking tapes are commonly used to mark areas of significance that do not pose immediate hazards but require clear marking for operational efficiency or compliance purposes.

For instance, blue floor marking tapes may outline designated storage areas, traffic lanes for forklifts or other equipment, or locations for other shipping departments. Additionally, blue floor marking tapes indicate areas reserved for specific purposes, such as maintenance zones or quarantine areas, ensuring clarity and orderliness in the workplace environment.

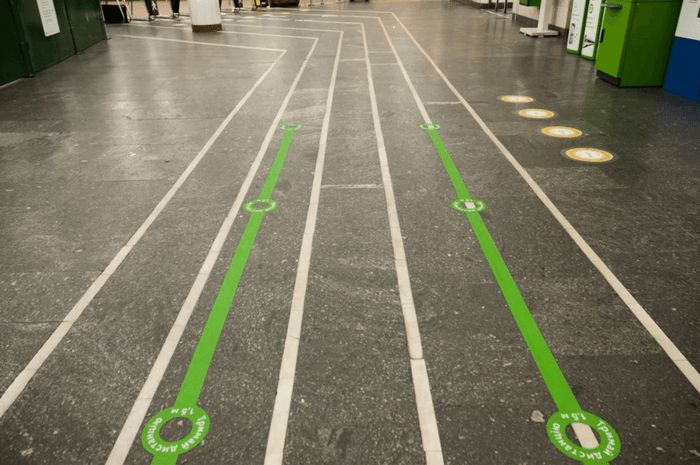

Green floor marking tapes designate safe routes, pathways, or emergency evacuation routes within a facility. The green colour signifies safety and serves as a visual cue to guide individuals toward exits or designated assembly points during emergencies.

Additionally, green floor marking tapes may be employed to keep areas for first aid stations, safety equipment storage, or other safety-related facilities. By using green floor marking tapes, business owners ensure safe and efficient shipping operations, knowing that employees and visitors can easily navigate the premises in an emergency.

White floor marking tapes are commonly utilized to mark boundaries, pathways, or designated areas for specific shipping processes. The neutral white colour provides a clear contrast against coloured surfaces, making it ideal for applications where high visibility is necessary without conveying a specific warning or safety message.

White floor marking tapes may outline workstations, aisles, or inventory zones, aiding in efficiently organizing space and shipping operations.

The distinctive orange colour is widely recognized as a warning sign, making these tapes ideal for marking hazards or temporary obstructions. Typical applications of orange floor marking tapes include:

● Highlighting areas under construction

● Indicating temporary storage zones

● Marking off areas where maintenance work is in progress

Plus, they may be used to warn individuals of potential tripping hazards, machinery operation zones, or areas with restricted access. By clearly delineating these areas with orange floor marking tapes, employers can help prevent accidents, promote workplace safety, and ensure compliance with safety regulations.

Unlike other floor tapes that focus on visibility and warning, black tapes are primarily used for masking or covering existing markings, imperfections, or unwanted lines on floors. They provide:

● A practical solution for hiding outdated markings

● Covering up errors

● Concealing areas that are no longer relevant to current operations

Black floor tapes can also be used for aesthetic purposes, creating clean and uniform surfaces within a facility. By effectively camouflaging unwanted markings or imperfections, black floor tapes maintain a professional appearance while ensuring functional efficiency within the workspace environment.

Reflective floor tapes are designed to serve safety and navigational purposes in warehouse layouts where visibility is essential for preventing accidents and promoting efficient navigation.

The reflective properties of these tapes make them highly visible from a distance, ensuring that they catch the attention of workers and visitors even in dark environments. Their common use includes:

● Marking emergency exits.

● Guiding pedestrians along walkways.

● Delineating traffic lanes for vehicles.

● Highlighting potential hazards such as protruding equipment or uneven surfaces.

Floor tapes offer numerous advantages in incoming shipments and the receiving process. Here are some of them:

Using different colours or patterns of floor tapes can help design specific areas for different stages of the shipping process. This strategy helps optimize incoming inventory, organize order fulfillment processes, and ensure effective inventory management.

Additionally, marked production areas aid in preventing confusion among warehouse staff, facilitating efficient coordination and reducing the risk of errors or delays in shipping operations. Implementing floor marking tapes to assign production areas in a shipping warehouse contributes to a more organized, streamlined, and effective distribution process.

Floor tapes are highly visible markers that guide individuals to designated areas, pathways, or safety zones. Using different colours, patterns, or shapes, floor marking tapes effectively communicate important information, such as indicating pedestrian walkways, emergency exits, or hazardous areas.

This visual guidance enhances safety protocols by helping individuals navigate the space more efficiently and avoid potential hazards. Additionally, floor marking tapes improve organization and productivity by ensuring that everyone within the facility can quickly identify specific locations or follow established workflows.

These visible markers delineate safe pedestrian routes and guide traffic flow throughout the facility.

Using distinct colours or patterns, floor marking tapes effectively communicate designated walkways, ensuring that employees and visitors can navigate the space safely and efficiently. This clear division of lanes reduces the chance of accidents and collisions and improves general workplace organization and workflow.

These tapes serve as highly visible warning signs, alerting employees and visitors to potential dangers and helping to prevent accidents. By using distinct colours or patterns, floor tapes effectively communicate the boundaries of hazardous zones, such as areas with heavy machinery, electrical hazards, or slippery surfaces.

This proactive approach to hazard identification enhances safety protocols and ensures compliance with regulatory standards. Additionally, marking off hazardous areas with floor marking tapes helps to minimize the risk of injuries and property damage, contributing to a safer and more secure workplace overall.

Floor marking tapes serve as clear visual indicators that help organize and identify specific areas for storing goods, packages, or equipment. Using different colours, patterns, or shapes, these tapes assist in creating adequate space for various types of inventory, facilitating easy navigation for employees.

This approach to storage designation enhances inventory management processes, streamlines order fulfillment, and reduces the risk of errors or misplaced items.

You may be wondering why having an optimized shipping area is so essential. Well, let us break it down for you. Here are a few reasons why it's such a big deal:

By carefully structuring your warehouse layout, you can streamline the flow of goods in and out of the facility, reducing the time spent sorting, searching, and handling shipments. Clear labeling and designated spaces for different types of products enable workers to locate items quickly, minimizing errors and delays.

Additionally, an organized layout facilitates smoother communication and coordination among warehouse staff, leading to faster processing times and improved overall productivity.

By clearly delineating designated areas for loading, unloading, and movement of goods, companies can mitigate the potential for collisions and mishaps involving personnel, machinery, and inventory.

Implementing safety protocols and signage in these organized zones helps employees adhere to established procedures, minimizing the likelihood of accidents such as slips, trips, and falls. Furthermore, maintaining an orderly layout reduces clutter and congestion, creating a safer working environment with improved visibility and maneuverability for workers and equipment alike.

Shipping companies can successfully monitor and control inventory levels by having clearly defined and structured zones for incoming and outgoing shipments. With designated places for different products, items are easier to manage and identify, reducing the danger of stockouts or overstocks.

Also, standardized arrangement and labeling allow for reliable monitoring of inventory movements, resulting in enhanced insight into stock levels and turnover rates. This systematic method reduces the possibility of errors, such as misplaced or lost items, and allows for quick replenishment and order fulfillment.

Shipping warehouses can limit the risk of accidents and injuries by establishing clear delineations and designated areas for loading, unloading, and moving items. Employees are more likely to follow established processes when proper signage and safety standards are in place, reducing the possibility of accidents.

Moreover, keeping these zones organized minimizes clutter and congestion, increasing visibility and accessibility for personnel and equipment. This systematic approach produces a safer working environment and promotes a culture of accountability and awareness among shipping warehouse employees.

By carefully structuring the warehouse framework, shipping companies may make the best use of available space while efficiently handling a wide range of shipments. With specified zones for loading and unloading, you can streamline the flow of goods and avoid congestion, assuring smooth operations and faster turnaround times.

A systematic structure improves inventory visibility and accessibility, saving time and effort on inventory management activities. This strategic strategy enhances shipping and receiving efficiency and increases overall warehouse productivity and effectiveness.

The innovative use of floor marking tapes to organize shipping and receiving areas provides several benefits to organizations in today's logistics environment. These tapes, commonly used for safety and directing purposes, have proven to be useful instruments beyond helping optimize the entire warehouse operations.