Floor markings, particularly when using high-quality floor marking tape, play a pivotal role in maintaining a structured and safe work environment. Industrial floor tape is a key component in this process, offering clear demarcation lines within facilities with floor tape. Industrial floor tape is widely recognized for its ease of installation, durability, and adaptability. Numerous enterprises across various sectors rely on the robust floor safety solutions that warehouse floor marking provides, underscoring its critical role in today's workplace safety. Among the options available, Mighty Line floor tape stands out for its industrial strength and versatility. It comes in an array of colors, designs, and functionalities to cater to a wide range of applications, making it a top choice for floor marking tape.

As businesses continue to prioritize floor safety and organization, understanding the proper use and selection of Mighty Line floor tape is crucial. This guide delves into the 5S implementation, offering insights on choosing the right tape and its role in reinforcing safety within the workplace.

Understanding the 5S Method and Its Impact on Floor Marking

The 5S method, a cornerstone of lean manufacturing. The 5S workplace organization methodology, known for enhancing safety and organizational efficiency, has significantly influenced workplace organization and safety. Through strategic use of floor marking and safety signs, the 5S approach is practically applied to improve the work environment.

- Sort (Seiri):To eliminate unnecessary items from the workplace, floor markings in factory settings play a vital role. They designate specific areas for essential tools and materials, aiding in the maintenance of warehouse safety by making it easier to identify and clear out what's unnecessary.

- Set in Order (Seiton):To organize necessary items, using color-coded marker tape, such as Mighty Line Floor Tape, can help delineate areas for equipment, inventory, and pedestrian pathways. This ensures that everything has a designated place, enhancing the functionality of tape for floors.

- Shine (Seiso):Maintain a pristine workplace. Clear and well-maintained floor markings not only contribute to a cleaner environment but also enhance floor safety by delineating specific zones for waste disposal and the storage of cleaning equipment with clear maintenance signs.

- Standardize (Seiketsu):Standardize for efficiency. By standardizing color codes for floor markings in line with OSHA signs and ANSI standards, a facility can boost clarity and operational efficiency. Red can be designated for fire equipment locations, while yellow typically warns of general caution areas.

- Sustain (Shitsuke):Conduct regular audits. To ensure floor marking tape remains a reliable guide for behavior and OSHA compliance, it's crucial to perform regular audits. This practice helps maintain the visibility and accuracy of the markings, thereby preserving safety standards.

- Implementing 5S Floor Marking Strategies:

- OSHA Regulation 1910.144(a): Comply with safety regulations. Adhering to OSHA's guidelines for physical hazard markings is vital, and using high-quality, durable products like Mighty Line Floor Tape for osha signage requirements ensures work areas, aisles, and emergency exits are clearly delineated.

- Color Coding and Efficiency: Align with safety and efficiency. Standardizing floor marking colors is not just about compliance with ANSI guidelines and osha hazard signs; it also optimizes operations. Utilizing red for fire protection equipment and yellow for caution areas facilitates rapid identification and response in emergencies. Also helps with following NFPA 101 standards.

- Advantages of Floor Marking Tape over Paint: Opt for quality floor solutions. Selecting industrial floor tape like Mighty Line Floor Tape brings advantages such as easy application and removal, resistance to heavy traffic, and the option to incorporate pictograms and patterns for better communication.

- Key Considerations for Effective Floor Marking:

- Avoiding Overuse or Underuse:Balance is key in floor marking. Striking the right balance ensures that safety signs convey essential information effectively without causing information overload. It's important to mark aisle widths, inventory zones, and egress safety paths clearly.

- Training and Awareness:Employees must engage in safety training to grasp the importance of various colors and patterns in floor markings, reinforcing the 'unofficial sixth S'—Safety, and adhering to safety signs OSHA guidelines.

- Long-term Savings:While the initial cost of high-quality Mighty Line Floor Tape may be higher, its industrial strength and durability lead to long-term savings and efficiency gains, making it a smart investment for a safe and well-organized workplace.

Incorporating Mighty Line Floor Tape into a 5S implementation not only bolsters safety and organization but also complements lean systems by introducing a facility-wide color-coding system, visibly weaving safety into the fabric of daily operations.

The Role of Floor Tape in Workplace Safety

Floor tape plays an indispensable role in enhancing workplace safety. Mighty Line Floor Tape enhances floor safety, primarily by organizing space, directing traffic, and highlighting potential hazards. Its versatile application can significantly aid in accident prevention across various work environments. Here are some insights into how floor tape contributes to workplace safety:

- Guiding Movement and Traffic Safety:

- Designates pedestrian walkways, ensuring a safe path away from moving machinery or vehicles.

- Marks areas where forklifts and other industrial vehicles operate, reducing the likelihood of collisions.

- Indicates directions of movement, helping to manage the flow of traffic and minimize confusion.

- Highlighting Hazards and Exit Routes:

- Utilizing different colors to signal various hazards, such as yellow for caution and red for danger, aligns with OSHA warning signs and helps employees quickly recognize and respond to potential risks, effectively functioning as a caution sign.

- Glow-in-the-dark and reflective tapes are essential for marking emergency exits and access routes, crucial for safe egress in compliance with egress regulations during power outages or low-light conditions.

- Meeting OSHA standards for marking permanent aisles and passageways, Mighty Line Floor Tape ensures legal OSHA compliance and enhances workplace safety, acting as a vital component of osha signage. Our floor signs can be used to be to boost safety for ANSI caution sign. Other floor signs include yield signs, caution sign, do not enter sign, do not step sign, no step sign, stop floor signs, PPE required floor sign, and other OSHA safety signs. These safety signs really help show that you are being safe we can make custom a OSHA sign as well. We have produced custom OSHA caution sign and other OSHA warning sign. One of the most popular is the fire extinguisher floor sign that blocks out the fire extinguisher.

- Floor signs can enhance workplace safety regulations by complementing tape markings with vivid safety posters and reminders, further reinforcing safe practices with clearly visible safety signs. Mighty Line PPE floor signs can show safety shoes, lockout tagout, forklift safety, SDS or safety data sheets areas, safety glasses required, yield sign, safety vest required, hazardous waste, eye wash, chemical hazard, high voltage, electrical safety, emergency exit, PPE Signs, safety harness required, hard hat stickers, or flammable floor signs. These floor signs show that safety first is a mentality in the workplace. They help GEMBA principles, ANSI compliance, improve safety scoreboards.

Mighty Line floor tapes are celebrated for their durability and variety, presenting an effective solution for implementing safety measures. These industrial floor tapes come in an array of sizes, styles, and colors, including specialized anti-slip options, reflective, and glow-in-the-dark features, ensuring a fit for every workplace's unique requirements. Mighty line floor tape can be used as a floor caution tape. By choosing the right Mighty Line product and applying it strategically, businesses can foster a safer, more organized, and efficient work environment. Mighty Line yellow floor tape is the most popular. This floor marking tape yellow is used in a wide variety of industries. The floor tape yellow is popular for egress areas and other users use it as a floor safety tape.

Selecting the Right Mighty Line Floor Tape: Types and Applications

Selecting the right Mighty Line floor marking tape for your facility's needs is crucial, and it involves a deep understanding of the diverse options and their specific applications. Here's a comprehensive breakdown to streamline your tape mark selection process:

Mighty Line Floor Tape Varieties

- Standard Mighty Line Floor Tape:·

- Widths Available: 1", 2", 3", and 4" and 6"

- ColorsMighty Line offers 11 different options to suit any industrial facility, including a clear version of the tape in 2", 3", 4", and 6" widths, which can be utilized alongside warehouse labels for optimal organization and safety.

- FeaturesThe industrial floor tape is scuff-resistant, easy-to-clean, and exceptionally durable, even in high traffic conditions. Each roll extends to 100 feet, offering high-contrast color patterns that ensure optimal visibility and safety in busy areas.

- Ideal For: Marking aisles, warehouse floors, workshop areas, and hazardous zones.

- Mighty Line Anti-Slip Safety Floor Tape:

- Purpose: Provides extra traction and slip resistance.

- Ideal For: Areas prone to slips and falls, ensuring additional safety measures in high-risk zones.

Specialized Options

- Mighty Line MIGHTY TAC Anti-Slip Floor TapeThe Anti-Slip Safety Floor Tape, similar in design to other safety tapes, is specifically engineered for areas with slip risks to prevent slips effectively, providing robust traction and enhancing overall safety.

- Custom printed floor tapes & 5s ShapesMighty Line's selection offers versatility with tapes for lines and shapes, including inline printed tape that allows for customized messaging and directional signs, guiding traffic and conveying important information within the facility.

- Mighty Line Floor SignsAn innovative solution for heavy duty floor signage, these signs are crafted with industrial strength durability to meet the demands of your application.

Selecting Based on Application Needs

When selecting the right Mighty Line Floor Tape, take into account the facility conditions and requirements to ensure optimal floor marking tape performance.

- Traffic Type: High-traffic areas benefit from the Ultra Durable or Anti-Slip options.

- Environmental ConditionsTo choose a tape that offers UV resistance and stands up to chemical exposure, water, and extreme temperatures, evaluate these factors carefully.

- Visibility Needs: Choose high-contrast colors and patterns to ensure clear communication and safety signaling.

- Floor Condition: For older or less perfect floors, Ultra Durable Tape provides a reliable solution.

By comparing your facility's specific needs with the attributes of various Mighty Line Floor Tape options, you can pick a floor marking tape that bolsters safety efficiency in your workspace.

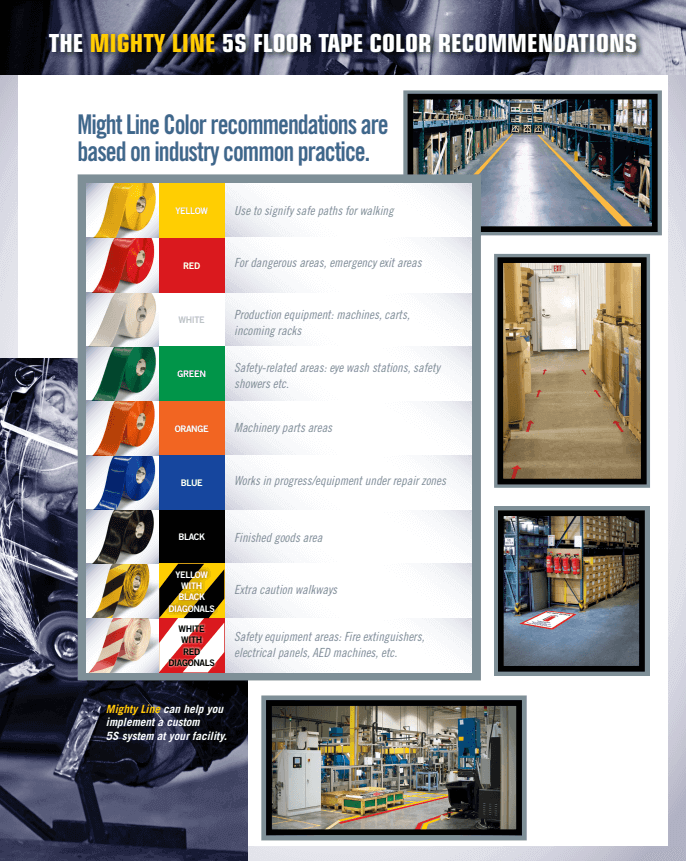

Color Coding and Line Width Standards

The strategic application of Mighty Line Floor Tape, with its color coding and line width standards, can substantially improve floor safety in your facility for safety and organization. Mighty Line offers warehouse floor marking guidelines. Here’s a detailed guide to help you understand and apply these standards effectively:

Color Coding Standards

- Yellow:Mighty Line Floor Tape effectively designates aisles, traffic lanes, and caution areas, serving as the standard for marking physical hazards with clear caution signs. These floor signs are safety signs that can be identified as accident prevention tags:

- Applications: Walkways, edges of aisles, and areas with increased trip hazards.

- White: Used for equipment and fixtures (workstations, racks, etc.) that are not color-coded otherwise.

- Applications: Traffic lanes, equipment storage locations.

- Red: Signals fire-related hazards, emergency switches, and stop buttons on hazardous machines.

- Applications: Fire safety equipment locations, emergency exits, OSHA caution signs, no stepping sign, stop floor signs, hazard communication signs, crane safety, 5s shadow board, pedestrian safety, high risk danger signs should only be used in those high risk areas to show those safety messages, floor signs to show as construction signs, floor signs to show lockout tagout signs, SDS signs, ESD control area, construction area, construction zone signs, confined space signs, job site signs, mine safety signs, and chemical storage signs. These are great to mark those danger confined space safety signs areas and improve workplace hazard communication.

- Blue, Green, Black:The distinct colors of Mighty Line Floor Tape are allocated for specific purposes, such as green for first aid signs and blue for machinery safety, ensuring materials and components are easily identifiable.

- Applications: Material storage areas (orange), first aid stations (green), machinery locations (blue).

- Striped Patterns (Red & White, Black & White, Black & Yellow): Used to mark areas around dangerous machines or to indicate hazardous areas.

- Applications: Areas requiring extra caution, near heavy machinery, or places with potential health hazards.

Line Width Standards

- Recommended Width:For optimal line visibility and adherence to safety standards, selecting widths between 2 inches and 6 inches is advisable, tailored to the specific application and corresponding traffic levels.

- Aisle Widths:In accordance with OSHA regulations, aisles should maintain a minimum width of 4 feet or extend at least 3 feet beyond the largest piece of equipment utilized, with aisle spacing clearly delineated by marking tape.

- High-Traffic Areas:In areas frequented by heavy equipment, adopting a line width of up to 6 inches can significantly enhance visibility and bolster heavy equipment safety.

- Why is Mighty Line floor tape different. It offers floor signs instead of painted safety stencils which can be difficult to work with. Mighty line is not a cheap floor vinyl tape, thin barricade tape or a thin floor tape for gyms. It is the robust industrial grade floor tape and floor sign. We have had retail, fire department, and warehouses through world use it. Mighty Line offers unique products like dot reflective tape, marine and imo signs, the industrial grade pavement marking tape for indoor use is the best in the world.

Implementation Tips

- Consistency is Key:Maintaining color consistency in your facility's safety markings is crucial to prevent confusion and uphold safety protocols universally understood by all employees.

- Visibility and Awareness:To ensure line visibility, select high-contrast colors that stand out against your floor's palette. For emergency egress routes, the implementation of photo-luminescent tape is a wise consideration.

- Compliance and Safety:Adhering to OSHA's guidelines for aisle widths and color codes not only ensures OSHA compliance but also contributes to a safer working environment through effective safety regulations.

Committing to these safety standards with appropriate color coding and line width is key to cultivating a well-organized and secure workplace. Mighty Line Floor Tape provides the resilience and diversity necessary to uphold these standards, facilitating a smooth operation and mitigating risks.

Best Practices for Installing Mighty Line Floor Tape

To guarantee the effective application and extend the floor tape lifespan of Mighty Line Floor Tape in your facility, adhere to these installation best practices with precision.

Step-by-Step Installation Process:

- Surface Preparation:

- Cleanliness is Key:Commence by rigorously cleaning the floor surface with a degreaser to eliminate any contaminants, ensuring optimal floor cleaning and adhesive adhesion. For floors heavily contaminated with oil or grease, it's advisable to apply an oily floor primer, such as Tri-Chem's Tri-Oil Stop, to bolster the tape's grip.

- Dry and Test for Moisture:Confirm that the floor is entirely moisture-free. For accurate moisture testing, affix a 2'x2' section of industrial stretch wrap to the ground using duct tape. Should moisture be detected on the wrap after several hours, it's essential to treat the area with a concrete sealer like V-Seal 101 or 102 before tape installation.

- Applying the Tape:

- Peel and Place:Gently remove the backing from the Mighty Line Floor Tape to reveal the sticky side. Start to lay the tape on the floor, rolling it out methodically for tape application that avoids air bubble prevention.

- Smooth Out:Employ a soft cloth or a roller during tape application to ensure a smooth application, pressing down for a secure fit between the tape and the floor surface.

- Cutting to Size:Should there be any need, utilize a box cutter or scissors for excess tape trimming to maintain a clean finish around the edges of the Mighty Line Floor Tape.

Advanced Tips for Durability and Aesthetics in Workplace Safety:

- Enhancing Adhesion:For enhanced tape adhesion, driving a heavy object along the tape line can be effective in removing air pockets and ensuring the tape adheres firmly to the floor.

- Mitering Corners:For a professional appearance, ensure that you overlap two layers of tape at corners, slicing through both layers diagonally to create mitered edges. Discard the excess tape and firmly press the mitered edges together for a neat finish.

- Replacing Damaged Sections:When undertaking tape replacement for a damaged tape section, carefully remove the compromised area and apply the new tape, using the mitering technique to achieve seamless integration.

Additional Considerations in Workplace Safety:

- Utilize Mighty Line’s Tools:Utilize the Mighty Liner Floor Tape Applicator for an easier and more uniform application, which is particularly beneficial when covering extensive areas.

- Warranty and Durability:Keep in mind that Mighty Line Floor Tape is backed by a 3-year limited warranty and boasts clean removal after prolonged use, positioning it as a cost-effective and dependable solution for marking your facility's floors.

By adhering to these best practices, you not only guarantee the effective application of Mighty Line Floor Tape but also foster a safer, more organized workplace that enhances efficiency.

Troubleshooting Common Floor Tape Issues in Workplace Safety

Despite the durability and dependability of Mighty Line floor tape, it's crucial to swiftly address any floor tape performance issues to maintain workplace safety and organization. Below are troubleshooting tips for common floor tape concerns:

1. Adhesive Failure:

- CausesDebris, contaminants, or the impact of extreme temperatures can lead to adhesive issues, resulting in bubbling, twisting, or peeling of the tape.

- Surface PreparationTo achieve optimal adhesion, it's crucial to follow meticulous cleaning procedures to eradicate grease, oil, and other contaminants. Employ a degreaser for heavy soiling and ensure comprehensive surface preparation, making the surface completely dry before any application.

- Temperature ConsiderationWhen installing Mighty Line floor tape, it's essential to apply it within the specified temperature ranges to ensure maximum effectiveness. For more demanding conditions, opt for specialized tapes crafted to withstand those extreme environments.

2. Application on Challenging Surfaces for Workplace Safety:

- Issue: Adhesive-backed floor marking tape may not adhere properly to cracked or uneven surfaces.

- Inspect Surface: Before application, assess the floor for cracks or unevenness.

- Alternative OptionsFor areas that pose a challenge, Mighty Line Dots or Segments may be the ideal floor marking options, offering ease of replacement. These alternatives are particularly suitable for uneven surfaces, ensuring effective floor marking.

3. Maintenance and Durability:

- Regular InspectionMaintaining safety communication in the workplace includes a regular visual inspection of floor tape for signs of wear, such as bubbling, twisting, or peeling. This practice helps in preserving a safe and communicative environment.

- Damaged SectionsImmediate replacement of damaged portions of floor tape is critical to prevent accidents and sustain visual communication. Combining floor tape with robust floor signs like Superior Mark® enhances durability and withstands industrial traffic.

Adhering to these troubleshooting tips and maintenance practices can significantly prolong the life of your Mighty Line floor tape, ensuring it continues to fulfill its role effectively within your facility. Regular upkeep and careful application are fundamental to maximizing the advantages of floor marking solutions.

Conclusion of Floor marking tape in Workplace Safety

Throughout this comprehensive exploration, we've examined the diverse aspects of Mighty Line floor tape and its pivotal contribution to workplace safety and navigability, as well as compliance with regulations and regulatory standards. By encapsulating the core principles of the 5S methodology and showcasing Mighty Line's durable and adaptable floor marking solutions, readers gain the insights necessary for making informed decisions that enhance clarity, safety, and efficiency. The explanation of ANSI regulations Z535.1 color standards not only ensures regulatory compliance but also demonstrates the critical role of visual communication in industrial settings. Mighty Line offers various TDS or technical data sheets to show that its floor tape is anti-static and anti-microbial. These technical data sheets are great for safety

Compliance with these standards is not just about meeting regulatory compliance; it's integral to building a safety culture and achieving operational excellence. In an era where workplace safety is increasingly vital, the guidance provided here shines as a guiding light for companies striving to improve their safety protocols and boost organizational efficiency. Those interested in leveraging Mighty Line's comprehensive floor marking solutions to optimize their workspace will find invaluable resources here and learn more. Embarking on a safety journey towards a safer, more efficient workplace is made tangible through adherence to ANSI Z535.1 standards and the utilization of Mighty Line's robust floor marking products. This commitment lays the foundation for a work environment that is not only productive but also anchored in safety.

FAQs

What do the different colors of floor marking tape indicate in Workplace Safety?

The colors on floor marking tape serve specific purposes:

- Blue, Green, and/or Black:The use of distinct storage area markings is crucial for delineating spaces where raw materials, finished products, and items in progress are kept, thereby streamlining inventory management and maintaining organization.

- Red & White:Markings that define clearance areas are essential for maintaining safety compliance, ensuring spaces in front of electrical panels, firefighting equipment, and safety gear remain unobstructed for accessibility and safety.

What is the significance of yellow and black floor tape for Workplace Safety?

Yellow floor markings serve as a visual cue for caution areas and signal the presence of physical hazards. The addition of black in a striped or checkered pattern alongside yellow increases visibility, reinforcing the hazard warning and promoting safety awareness.

What are the OSHA requirements for floor markings for Workplace Safety?

In line with OSHA guidelines, floor marking lines should be at least 2 inches wide to be clearly visible, though a width of 2 to 6 inches is recommended for maximum effectiveness. Furthermore, aisles should maintain a minimum width of 4 feet or be 3 feet wider than the largest equipment used, ensuring safe and free movement throughout the facility.

What does the combination of red and white on floor tape signify in Workplace Safety ?

Red and white striped floor tape plays a crucial role in safety compliance, improving hazard communication standards, marking electrical safety areas, marking confined space, marking zones that must remain unobstructed to maintain emergency access. These areas, especially in front of critical safety equipment and electrical safety areas such as electrical panels and firefighting apparatus, or battery charging areas are designated to ensure that nothing hinders their accessibility during urgent situations.

Workplace Safety References

Safety Stripes Podcast and Blog

Uline Mighty Line Floor Tape

Grainger Mighty Line floor tape

Fastenal Mighty Line floor tape

Home Depot Mighty Line floor tape