No Products in the Cart

This is about AGVs or Automated Guided Vehicles

Dave Tabar talks Mighty Line floor tape and Automation

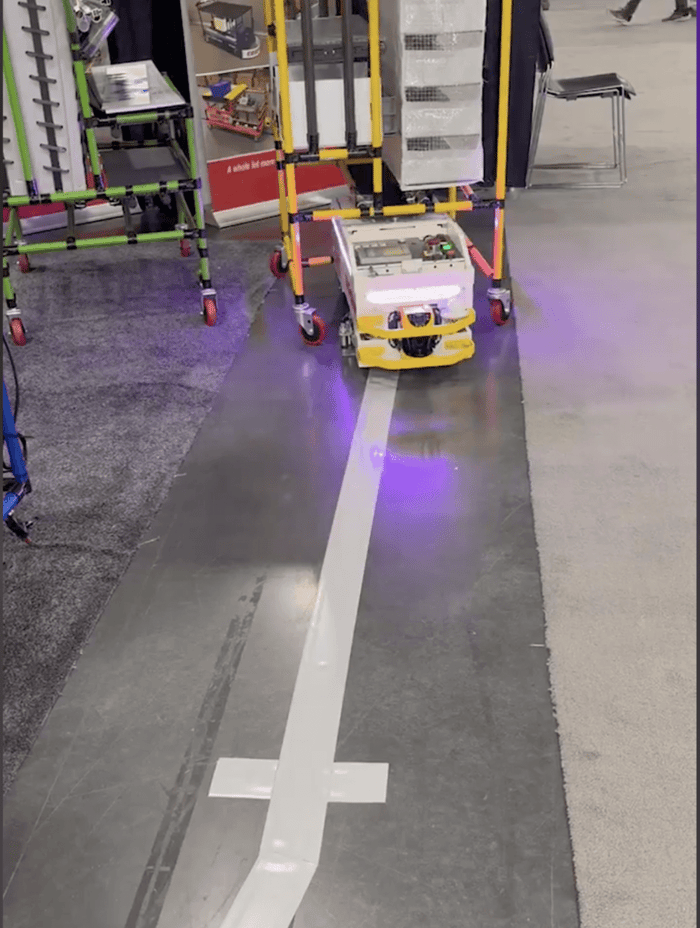

In today's fast-paced industrial landscape, automation has become a crucial factor in enhancing efficiency and productivity. One key component of successful industrial automation is the use of automatic guided vehicles (AGVs) and AGV floor tape. These innovative automation systems streamline material handling processes, optimize traffic control, and improve overall safety in warehouses, distribution centers, and manufacturing facilities.

This article will delve into the world of AGV floor tape and its vital role in enabling effective agv automation with autonomous guided vehicles. We will explore the different types of AGVs and floor tape, such as glow-in-the-dark tape and magnetic tape, and their specific applications in various industries, including agv manufacturing and warehousing. Additionally, we will provide essential floor tape installation guidelines, floor tape maintenance tips, and troubleshooting advice to ensure the smooth operation of your AGV system. By the end of this article, you will have a comprehensive understanding of how Mighty Line floor tape and Mighty Line floor signs can revolutionize your agv factory's automation capabilities.

AGV floor tape, also known as automated guided vehicle tape or Mighty Line floor tape, plays a crucial role in the successful implementation of AGV robots in various industrial settings. This specialized industrial floor tape is designed to provide clear, visual paths for AGVs to navigate through facilities, ensuring efficient and safe operations.

Mighty Line floor tape is typically made of durable materials such as vinyl or polyester, which can withstand the wear and tear of constant AGV traffic. This heavy duty floor tape is available in various colors, allowing for color-coding of different routes or zones within a facility. This color-coding enhances the organization and clarity of AGV pathways, making it easier for both the vehicles and human operators to understand the layout.

The importance of AGV floor tape lies in its ability to:

The use of AGV floor tape is particularly beneficial in industries such as agv manufacturing, warehousing, and logistics, where the efficient movement of materials is critical to overall productivity. By implementing Mighty Line floor tape and signs, companies can create a well-organized, safe, and efficient environment for their AGV forklifts and other types of AGVs, ultimately leading to improved operational performance and cost savings.

In conclusion, AGV floor tape is an essential component of successful AGV integration in industrial settings. Its ability to define clear paths, enhance safety, improve efficiency, facilitate flexibility, and simplify maintenance makes it a valuable tool for companies looking to optimize their material handling processes through agv automation.

There are several types of AGV floor tapes available, each designed for specific applications and environments. Choosing the right type of Mighty Line floor tape is crucial for ensuring optimal performance and longevity of your automated guided vehicles systems. Let's explore the different types of AGV floor tapes and their applications:

Solid-colored vinyl tapes, such as Mighty Line floor tape, are the most common type of AGV floor tape. They are durable floor tape, easy to apply, and provide excellent visibility for both AGVs and human workers. These tapes are available in various colors, allowing for color-coding of different routes or zones within a facility. Some common applications of solid-colored vinyl tapes include:

Magnetic tapes are specially designed for AGV systems that utilize AGV sensors for navigation. These tapes contain magnetic particles that create a magnetic field, which the AGV's sensors can detect and follow. Mighty Line floor tape helps cover for these magnet tapes and protect them. Magnetic tapes offer several AGV benefits, such as:

Magnetic tapes are commonly used in industrial environments where precision and reliability are critical, such as agv manufacturing plants and electronics assembly line AGVs.

Matte Finish floor tapes, also known as AGV floor tape can be custom made for your robots or agv vehicles

Clear floor tape making them highly visible to protect QR codes or bar codes for your AGV vehicles. These tapes are commonly used in conjunction with AGVs equipped with optical sensors or vision systems. Some applications of clear floor tapes include:

Embedded tapes are designed for permanent installation in facilities with high traffic or harsh environmental conditions. These tapes are typically installed in recessed channels or grooves in the floor, providing a flush surface that minimizes the risk of damage from vehicle traffic or heavy loads. Embedded tapes are ideal for:

Embedded tapes offer a long-lasting solution for AGV navigation systems, reducing maintenance requirements and ensuring consistent performance over time.

When selecting the appropriate type of Mighty Line floor tape for your AGV system, consider factors such as the navigation technology used by your AGVs, the environmental conditions of your facility, and the specific requirements of your AGV applications. By choosing the right type of AGV floor tape, you can optimize the efficiency, reliability, and safety of your automated guided vehicles systems.

Proper floor tape installation of Mighty Line floor tape is crucial for ensuring the smooth operation of automatic guided vehicles (AGVs) in industrial settings. The following guidelines will help you effectively implement AGV floor tape in your facility:

By following these installation guidelines and using high-quality Mighty Line floor tape and signs, you can create a reliable and efficient AGV navigation system in your facility. Proper installation and maintenance will minimize downtime, enhance safety, and optimize the performance of your automated guided vehicles.

Proper maintenance and troubleshooting of Mighty Line floor tape are essential for ensuring the smooth operation of automatic guided vehicles (AGVs) in industrial settings. Regular inspection, cleaning, and replacement of damaged sections can help prevent navigation errors and minimize downtime.

To maintain the integrity of the AGV navigation system, it is crucial to inspect the Mighty Line floor tape regularly for signs of wear, damage, or debris. Any torn or damaged sections should be promptly replaced to avoid potential AGV routing issues. Keeping the route clean and uncluttered is also important for stable AGV operation.

When encountering navigation errors, showing AGV routing accessibility information for control points can help identify the source of the problem. By right-clicking on the destination control point and choosing "Show AGV Routing Accessibility," various path transfers will be highlighted in blue, indicating points on the network that can reach the target control point. If a task executer cannot reach the control point, following the assumed path from the task executer to the destination can reveal where there is a break in the path links.

In some cases, AGV paths may lose or fail to properly create links to their neighbors during the model-building process. This can be resolved by manually refreshing the path links through the path's right-click menu. Refreshing the links will prompt the network to re-analyze the geometry of the paths and re-link them with their neighbors, enabling proper AGV routing.

Accumulation behavior can also introduce complexities and potential problems in AGV systems. When using accumulation, it is essential to understand how it works and its interaction with the standard allocation logic used for control points and control areas. In close-quarter intersection areas that use control areas to mutually exclude traffic, the two allocation schemes may "fight" with each other, causing deadlocks. To mitigate this issue, consider creating a special accumulation type designed for close-quarter intersections or turning off accumulation in those areas and relying on control areas for traffic management.

By following these maintenance and troubleshooting tips, and leveraging high-quality products like Mighty Line floor tape and Mighty Line floor signs, you can ensure the reliable and efficient operation of your AGV system. Regular inspection, cleaning, and prompt replacement of damaged sections, combined with a thorough understanding of AGV routing and accumulation behavior, will help minimize downtime and optimize the performance of your automated guided vehicles.

In conclusion, implementing AGV floor tape and automatic guided vehicles can significantly enhance the efficiency, safety, and productivity of industrial facilities. By understanding the different types of Mighty Line floor tape available, following proper installation guidelines, and maintaining the AGV navigation system through regular inspection and troubleshooting, companies can optimize their material handling processes and achieve substantial cost savings.

As the industrial landscape continues to evolve, embracing automation technologies like AGVs and Mighty Line floor signs will become increasingly crucial for businesses to remain competitive. To learn more about Mighty Line floor tape and floor signs for AGVs, visit their website and discover how these innovative solutions can revolutionize your facility's automation capabilities.

AGVs play a crucial role in manufacturing environments by facilitating the movement of materials or components. They efficiently transport partially completed goods through various stages of production, from storage areas to production lines or between different workstations. This optimizes the flow of goods through the manufacturing process, enhancing productivity and efficiency.

For processes such as distillation that involve high volume production, Fixed Automation is recommended. This type of automation system uses dedicated equipment designed for a fixed set of operations, making it highly efficient for continuous flow and discrete mass production systems. Examples include conveyors, paint shops, and transfer lines, which are integral to processes like distillation.

To construct an AGV, five key elements are necessary: a Navigation System to guide the AGV through its environment, a Safety System to prevent accidents, a Power System to supply energy, a Motion System to enable movement, and a Vehicle Controller to oversee operations. These components work together to ensure the AGV functions effectively and safely within its intended environment.

AGV stands for Automated Guided Vehicle. It refers to a type of automated vehicle specifically designed to autonomously transport products or materials within a manufacturing facility or warehouse. AGVs are instrumental in automating the internal transportation of goods, thereby increasing efficiency and reducing manual labor in these settings.

References

https://mightylinetape.com/collections/clear-floor-tape

https://mightylinetape.com/pages/mighty-line-floor-tape-the-best-floor-marking-tape

https://mightylinetape.com/products/4-yellow-solid-color-floor-tape

https://mightylinetape.com/a/blog/agv-safety-risks-and-precautions

https://www.mightylineminute.com/